Product n 2. Why is the condom called “rubber product number two”? Equipment and weapons

There are several opinions regarding the origin of the name. One of them says that in the USSR they numbered different kinds rubbers that differ from each other in density. So, “Rubber product No. 1” was called, “Rubber product No. 2” was a condom, No. 3 was an eraser, and “Rubber product No. 4” was galoshes. There is also a version that in pharmaceuticals the “No” sign indicated the number of pieces of the product in the package. For example, if there are 10 tablets in a plate, then the number 10 will appear on the blister, and in those days one package contained 2 condoms. But in fact, No. 2 only indicated the size of the product.

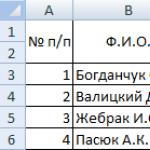

The first condoms began to be produced in 1936 at the Bakovsky plant. This was due to Stalin’s decree banning abortion. There were three types of products in total, differing in size: No. 1 - small, No. 2 - medium, and No. 3 - large. Products No. 1 were not in demand for obvious reasons: not everyone calmly admits that their dignity is below average size, and for women in those days it was considered shameful to purchase this product. Condoms number three were too big, so condom number 2 became the most popular product, and the remaining types, most likely, simply stopped being imported and then released. By the way, the average size suited almost all men, because... was designed to be 180 mm long and 54 mm wide, comparable to the European XXL–.

Condoms were about 2-3 times thicker than modern ones, but they could withstand a load of up to 200 kg per square centimeter.

Release forms

The quality of the product and packaging have not changed for decades, as has the production technology. The product was sold only in pharmacies, was made of dense, hard rubber, and was sprinkled with talcum powder to prevent sticking. The color of the rubber was yellowish and it smelled quite unpleasant. Condoms were packaged 2 in a cardboard package, which cost 43 kopecks, and after the reform of 1961 - 4 kopecks. People at that time called them that way – “4 kopecks”. In the mid-60s, protective equipment began to be made in individual packages, and in the 70s, the first domestic copies appeared, similar to the modern version: with a sperm accumulator, in silicone lubricant and foil packaging. The new GOST for condoms was adopted in 1981 - now the size markings were lettered - A, B and C. And during perestroika, multi-colored versions began to be produced: red, blue and green.

In our country at the end of the 1980s, about 200 million pieces of rubber products were sold annually.

“Rubber Product No. 2” was in great demand, despite all the inconveniences and shortcomings, especially during times of shortage. We bought condoms for future use, 10 or more pieces each. If it was possible to get imported analogues, they were even presented as a gift for the holidays.

The first Soviet short-range air-to-ground guided missiles made it possible to significantly increase the strike capabilities of the front-line. However, their use was associated with certain difficulties. In particular, the X-66 and X-23 missiles required the pilot to control the flight of the missile until it hit the target. In addition, they carried a relatively light warhead, which is why they could not hit enemy fortifications, etc. objects. In 1970, the USSR Ministry of Defense initiated the development of a new aircraft-guided munition that could effectively solve the assigned tasks, but would not inherit the shortcomings of its predecessors.

The new guided missile project was designated X-29. The development of this product was entrusted to the Molniya design bureau (now NPO Molniya), and M.R. became the chief designer. Bisnovat. Molniya specialists completed most work, but in the mid-seventies they were forced to stop participating in the project. Due to the mass of orders for the Buran program, the Molniya Design Bureau transferred the documentation for the X-29 project to the Vympel Design Bureau (now the Vympel State Design Bureau). This organization already had extensive experience in creating guided weapons, including aviation systems. Vympel employees under the leadership of A.L. Lyapina completed the development of the project and began mass production of new ammunition. Currently, the production and support of X-29 missiles is carried out by the Tactical Missile Weapons Corporation (KTRV), which includes the Vympel State Design Bureau and other specialized organizations.

Existing guided missiles were aimed at the target with the direct participation of the pilot or aircraft automation. To simplify combat work, it was necessary to abandon radio commands, etc. systems, creating new homing heads operating in the “fire-and-forget” mode. It was decided to equip the new X-29 product with a promising seeker that would provide such an application. In view of the requirements for launch range (up to 10-12 km), it became possible to equip the missile with an optical guidance system. As a result, they decided to make two modifications of the ammunition with the maximum degree of unification, equipped with different seekers - television and laser.

Unified units

For some reasons, the X-29 missile received the same aerodynamic design as previous guided weapons of this class - “duck”. The rocket has a cylindrical body with a length of 3875 mm and a diameter of 400 mm. In the bow of the hull there is a set of X-shaped destabilizers, behind which there are rudders of a similar design with a span of 750 mm. X-shaped wings with ailerons with a span of 1.1 m are attached to the rear part of the hull. Structurally, the hull is divided into five compartments that accommodate various equipment. The head contains a homing head, which is why missiles of various modifications differ in the shape of the head fairing. Behind the head compartment there is a volume with a control system. The middle part of the hull is occupied by a high-explosive fragmentation warhead, behind which a solid-fuel rocket engine is placed. The tail section houses the engine nozzle, around which the aileron drives are located.

In the second compartment of the X-29 family missile body there is a unified autopilot, which ensures that the missile is kept on a given course and controls the rudders. It receives data from the seeker used and, based on it, generates commands for the steering gears. Ailerons on the wings are used to control roll. Two pairs of rudders are responsible for control in the pitch and yaw channels. The steering wheels are connected in pairs (along control channels) and are driven by two steering gears (one for each channel). During launch, the rudders are moved to a position that ensures the distance of the rocket from the carrier aircraft. The rocket's electrical equipment includes a DC ampoule battery with forced heating. To start and ensure operation of the battery, a separate pyroblock is used that produces hot gas. The battery charge is enough to operate all systems for 40 seconds, which significantly exceeds the maximum possible flight duration.

Kh-29 missiles are equipped with a PRD-280 solid fuel engine with a thrust of up to 225-230 kN. Unlike the Kh-66, Kh-23 and Kh-25 missiles, the Kh-29 product has one engine nozzle located at the rear end of the body. Such design differences are due to the absence of a full-fledged instrument compartment in the tail of the body of the newer rocket. The engine starts with a slight delay after uncoupling from the carrier aircraft, due to which the hot gases of the engine do not damage the structure of the latter. The engine charge burns out in 3-6 s, accelerating the rocket to speeds of about 600 m/s. In this case, the average flight speed, taking into account gliding during uncoupling and gliding after combustion of the solid fuel charge, is at the level of 300-350 m/s.

Kh-29 guided missiles are equipped with a 9B63MN armor-piercing high-explosive warhead weighing 317 kg, which is approximately half of the product’s launch weight. The warhead is made in the form of a steel body weighing 201 kg, which has a cone-shaped head with thickened walls. Inside the case there are 116 kg of explosives. The design of the warhead is designed taking into account the need to destroy both manpower or unprotected equipment, as well as fortifications, buildings or ships. According to some reports, the design of the warhead allows it to penetrate up to 3 m of soil and 1 m of concrete. To avoid rebound when hitting the target surface at sharp angles, the warhead is equipped with an anti-ricochet device. The KVU-63 warhead fuse can operate in contact mode or detonate with deceleration. Contact sensors are located in the head of the rocket, next to the rudders, and also on the leading edges of the wings. The fuse operating mode is selected by the pilot before launch. Contact detonation is intended to destroy equipment and manpower, and deceleration is used to attack bunkers, concrete structures, etc. objects.

The X-29 project initially provided for a modular design with the ability to install a homing head of the desired model. By order of the Ministry of Defense, employees of the Molniya design bureau, and then the Vympel design bureau, first developed two versions of the seeker: laser and television. The version of the missile guided by reflected laser light was designated Kh-29L or “Product 63”, with a television head - Kh-29T or “Product 64”. Externally, these two types of missiles differ only in the shape of the head fairing, inside of which the homing head units are located. However, there is a slight difference in the starting weight of the products. The Kh-29L missile, ready for use, weighs 660 kg, the Kh-29T weighs 20 kg more.

Kh-29 missiles of both types were supplied in transport containers measuring 4.5x0.9x0.86 m (Kh-29L) and 4.35x0.9x0.86 m (Kh-29T). A missile with a laser seeker in a container weighs 1000 kg, with a television seeker - 1030 kg. For suspension on aircraft and launch, ejection devices AKU-58 and their modifications can be used.

Homing heads

The head of the Kh-29L missile has a shape formed by two conical surfaces, on which there are trapezoidal aerodynamic destabilizers that improve controllability and maneuverability in flight. At the head end of the fairing there is a transparent section through which the seeker “monitors” the laser illumination spot. In order to simplify the design and reduce the cost of production, the Kh-29L received a semi-active laser seeker of type 24N1, developed by the Geophysics Central Design Bureau under the direction of D.M. Khorola for the X-25 rocket. To carry out an attack, the carrier aircraft or ground gunner had to illuminate the selected target with a laser beam. In this case, the homing head must detect the light reflected by the target and guide the missile using the proportional approach method.

The method of using a missile with a laser seeker depended on the type of on-board equipment of the carrier aircraft. So, in the case of the suspended container “Prozhektor-1”, which ensured the movement of the laser beam only in the vertical plane, the rocket’s automation had to immediately work in guidance mode with control over two channels. In the case of using the more advanced Kaira or Klen systems with two-plane beam guidance, it became possible to rise to a certain height relative to the carrier aircraft and then perform a “slide”, which increased the effectiveness of the attack when launched from low altitudes.

Depending on the type of illumination equipment used, the carrier aircraft, after dropping the missile, could maneuver within certain limits. When using ground-based target designation equipment, the pilot could leave the target area after launch without risking coming under enemy anti-aircraft fire. The Kh-29L rocket could be launched at altitudes from 200 m to 5 km with a carrier speed of 600 to 1250 km/h. In this case, the minimum firing range was 2 km, the maximum – up to 10 km. It should be noted that due to the use of a laser seeker, the actual firing range depended on meteorological conditions and other factors interfering with the capture of the laser mark.

Homing head 24N1 of the Kh-29L missile

The use of the new autopilot in combination with the existing 24N1 laser homing head gave a very interesting result. The probable circular deflection of the Kh-25 missile, for which this seeker was created, reached 10 m. New devices were able to bring the CEP of the Kh-29L missile to 3.5-4 m, which made it possible to hit laser-marked targets with a high probability. However, actual performance under conditions combat use could seriously differ from those indicated due to various technical and tactical reasons.

The Kh-29T air-to-ground guided missile received a more complex and expensive television homing head, Tubus-2, created at NPO Impulse. While inferior to the 24N1 product in cost and simplicity, the Tubus-2 system simplified the attack of targets through the full implementation of the “fire-and-forget” principle. When assembling the missile, the television seeker is installed on the same mounts as the laser head of the Kh-29L missile.

Homing head "Tubus-2" of the Kh-29T missile

The Tubus-2 seeker has a cylindrical body with a hemispherical head fairing made of transparent material. The head contains an optical-electronic part and a target coordinator mounted on a movable gimbal. In addition, equipment is provided for processing video signals and transmitting data to the rocket autopilot. The video system of the Tubus-2 product in target search mode provides an overview of an area measuring 12°x16°. In automatic target tracking mode, the field of view is limited to angles of 2.1°x2.9°. The coordinator is capable of tracking targets moving at an angular velocity of no more than 10 degrees/s. The video camera produces an image with a quality of 625 lines, 550 lines, 50 Hz.

The method of combat use of the Kh-29T missile is as follows. The pilot, visually or using on-board surveillance equipment, must detect the target and place it in the surveillance sector of the television seeker. Next, using the missile’s video system, including the use of magnification, he must select a target and aim the aiming mark at it. To capture a target, the seeker “remembers” its features, such as the combination of contrasting light and dark areas. After reaching the permitted launch range, the pilot can uncouple the missile. The further flight of the rocket is carried out automatically. The missile independently monitors the target and aims at it. Before hitting, a “slide” is performed so that the missile can hit the target, such as a fortified structure, from above, with the greatest effectiveness.

Due to the maximum possible unification, the X-29 family missiles have similar characteristics. The X-29T with a television seeker can be launched from a height of 200 m to 10 km at a carrier aircraft flight speed of 600-1250 km/h. This ensures shooting at a range from 3 to 12 km. The circular probable deviation does not exceed 2-2.5 m. Moreover, the actual characteristics of the Kh-29T missile directly depend on various conditions and can vary widely.

The design of the Kh-29T missile: I - homing head: 1 - “Granit-7T-M1” lens; 2 - television camera with videocon; 3 - gyrostabilizer; 4 - blocks of the passive television target coordinator “Tubus-2”; 5 - destabilizer; 6 - power supply; II - control compartment: 7 - reaction contact sensors of the SKD-63 system; 8 - gas drives of rudders; 9 - steering surfaces; 10 - ampoule electric battery 8M-BA; 11 - electrical converter; 12 - control unit (equipment and filters); 13 - detachable plug connector; III - warhead: 14 - aluminum shells; 15 - steel body of the 9B63MN warhead; 16 - explosive warhead 9B63MN; 17 - front fastening unit; 18 - detonators with safety-remote devices 3B45.01; IV - engine: 19 - switching unit for the contact fusing device KVU-63; 20 - UPD2-3 squib cartridges for engine ignition; 21 - engine start checks and KVU-63; 22 - igniter; 23 - rocket engine solid fuel PRD-280; 24 - reaction cable contacts of the contact explosive device KVU-63; 25 - wing; 26 - rear attachment point; 27 - gas generator of the gas supply unit; V - nozzle and tail: 28 - filters and pressure regulators of the gas supply unit; 29 - aileron; 30 - aileron drive; 31 - engine nozzle.

New modifications

The development of the X-29 project, begun at the Molniya design bureau, was completed by the employees of the Vympel design bureau. The same organization carried out the tests. At the end of the seventies, both proposed types of missiles passed the full range of tests and necessary improvements. In 1980, the X-29L and X-29T products were adopted by the Air Force. Soviet Union.

During further development During the project, several new missiles were developed at the Vympel design bureau, differing from the basic Kh-29L and Kh-29T in some parameters, equipment used and purpose. On this moment The following modifications are known:

- UH-29. A training version of missiles designed for pilot training. It is a regular serial product with bright colors. Instead of the standard white color, they are painted red (entirely) or red with a white central section. When testing the Kh-29 missiles, as part of the armament complex of the Su-24M bomber, a missile with a red head and tail and a “checkerboard” red and white coloring of the central compartment was used;

- X-29ML. A missile with an updated laser guidance system, providing greater accuracy;

- X-29TM. An upgraded version of the missile with a new television seeker;

- X-29TE. Upgraded export version of the X-29T. According to some reports, the firing range has been increased to 30 km;

- X-29TD. Modification with an updated guidance system. According to some reports, it is equipped with a television seeker with a thermal imaging channel, ensuring use in night conditions;

- X-29MP. A missile with a passive radar homing head.

In the arsenals

The X-29 missiles were put into service in 1980, after the start of the war in Afghanistan. The first combat use of new ammunition took place only in 1987. Since April 1987, Soviet pilots regularly used this against various difficult targets. The use of optical guidance systems affected the effectiveness of missiles. So, in April 1987, Su-25 attack aircraft of the 378th oshap, armed with Kh-25 and Kh-29L missiles, were for the first time ordered to destroy warehouses carved into the rocks. Klen-PS aircraft systems were used to illuminate the target. Due to the smoke generated during the attack, two of the four launched Kh-29Ls were unable to home in on the target. In addition, target illumination in combat conditions presented a certain difficulty.

To increase the efficiency of using guided missiles in the 378th separate attack air regiment, with the assistance of specialists who came from the USSR, they built the so-called. BOMAN - "Aircraft gunner's combat vehicle." On the BTR-80, behind the turret, a Klen-PS rangefinder-target designator was installed, taken from a decommissioned Su-25 attack aircraft. Later, a “modification” of BOMAN appeared, in which the rangefinder-target designator could be retracted inside the armored hull. To search for a target on such vehicles, an optical sight from the NSV-12.7 machine gun was used.

The appearance of aircraft guidance vehicles soon affected the effectiveness of the use of guided aircraft weapons. When using such equipment, attack pilots only had to go to the launch line, lock on the target and launch missiles. Searching and illuminating the target was the responsibility of the BOMAN crew, and the vehicle could do its job while at a safe distance from the target. In addition, during combat work the vehicle stood in one place and did not move, thanks to which the gunner was able to clearly and accurately highlight the selected target. When illuminated from an aircraft, the laser spot could shift significantly from the intended aiming point.

During the remaining years of the war in Afghanistan, Soviet pilots used up about 140 guided missiles of several types. These weapons were mainly used to destroy protected complex targets, such as warehouses, etc. objects in mountain caves. The characteristics of the 24N1 laser seeker made it possible to hit the missile directly at the entrance to the cave. If there was an ammunition depot inside, then the 317-kilogram warhead of the Kh-29L missile left no chance for the enemy’s supplies and manpower. In addition, they practiced shooting at the cave roof above the entrance while setting the fuse to detonate with a delay. Due to high speed and a durable body, the warhead of the rocket was buried in the stone and collapsed the vault, trapping enemies and their property inside.

During the two wars in Chechnya, the Russian Air Force also made limited use of the Kh-29L and Kh-29T missiles. The relatively small number of missiles used was due to the difficult meteorological situation. Bad weather simply did not allow full use of all the capabilities of guided weapons.

In the eighties, X-29 missiles began to be supplied to foreign countries. Such weapons in different time purchased by Algeria, Bulgaria, Venezuela, East Germany, Iraq, Iran and other countries that purchased Soviet aircraft. In total, including the former republics of the Soviet Union, the X-29 family of missiles has been and remains in service in 26 countries.

Some foreign countries had experience using Soviet air-to-ground guided missiles. The first of foreign countries Iraq used X-29 missiles in combat during the war with Iran. Due to the enemy's sufficiently developed air defense system, the Iranian air force was forced to actively use high-precision guided weapons, suitable for striking without entering the enemy's missile strike zone. The Kh-29L missile carriers were Soviet MiG-23BN and French-made Mirage F1 aircraft. The aircraft's armament was also mixed, since they used both Soviet and French missiles. In addition, French laser equipment was used along with laser-guided missiles.

In the second half of 2000, during the Ethiopian-Eritrean conflict, the Ethiopian Air Force used Kh-29MP and Kh-29T missiles to suppress enemy air defenses. Su-25 aircraft, each of which carried two missiles with radar and television seekers, with fighter escort, were able to break through to the launch line and destroy the radar of the Eritrean Kvadrat air defense systems using the X-29MP. Next, the remaining anti-aircraft systems were “finished off” with Kh-29T missiles. A little later, Ethiopia attempted a similar strike, but this time the enemy managed to detect the attack in time and launch anti-aircraft missiles, which damaged one of the enemy Su-25s. However, the attack aircraft were able to destroy the air defense missile system radar, after which the “blinded” systems were hit by free-falling bombs from fighter-bombers.

The X-29 family of missiles can be considered a successful representative of domestic air-to-ground guided weapons. They have high accuracy guidance and great power of the warhead, allowing the destruction of various targets, including fortified buildings and underground structures. However, this weapon was not without its shortcomings. Laser and television guidance could only be carried out in good weather conditions, in the absence of artificial interference such as smoke or various aerosols. In addition, over time, the short launch range, which was included in the product requirements, became insufficient to protect the aircraft from the later appeared short-range air defense systems.

Although the X-29 family of missiles have both positive and negative features, they can be considered at least one of the most successful developments of their class created in our country. Moreover, at the time of their introduction and for some time after that, they were the most advanced domestic air-to-ground guided missiles.

Based on materials:

http://airwar.ru/

http://rbase.new-factoria.ru/

http://bastion-karpenko.narod.ru/

http://militaryparitet.com/

http://airforce.ru/

http://aviaros.narod.ru/

Markovsky V.Yu., Prikhodchenko I.V. Su-25 "Grach" attack aircraft. Armored successor to the IL-2 – M.: Yauza: EKSMO: 2011

Ctrl Enter

Noticed osh Y bku Select text and click Ctrl+Enter

Mi-28N " Night Hunter" / product 294 / R&D "Avangard-2" - HAVOC-B

Mi-28NM

All-weather night-day attack helicopter. In 1993, after the completion of the first stage of state testing of the Mi-28A attack helicopter, preliminary conclusion on the release of an initial batch of helicopters equipped with a set of equipment and weapons for use in daytime and limited adverse weather conditions. However, M.V. Weinberg, who by that time had become the general designer of the Moscow Helicopter Plant named after. M.L. Mil", decided to stop the development of the Mi-28A at the final stage of state tests and concentrate all forces and financial capabilities on the development of the Mi-28N combat helicopter ("N" - night) - R&D "Avangard-2" - round-the-clock and all-weather, with fundamentally a new integrated fifth-generation avionics system.

Tests. The first experimental Mi-28N helicopter was built in August 1996 and made its first flight on November 14, 1997 (test pilot V.V. Yudin and navigator S.V. Nikulin), and from April 30, 1997 it began undergoing factory testing flight tests. Four years later, the Mi-28N entered joint state tests (2001). Considering the great need for military vehicles of this type, the command of the Russian Air Force in 2002 accepted the Mi-28N as the main promising combat helicopter of the future, without waiting for the completion of tests. In June 2005, the second prototype of the Mi-28N began the test program. On March 4, 2006, after the successful completion of the first stage of state joint tests, a state commission chaired by the Commander-in-Chief of the Air Force Russian Federation Army General V.S. Mikhailov issued a conclusion on the release of the pilot batch of Mi-28N. In May 2006, the first production Mi-28N, board No. 32, joined state tests. State joint tests of the Mi-28N were completed on December 26, 2008 with the signing of a certificate of completion. 2 experimental and 7 pre-production helicopters took part in the GSI. On October 15, 2009, by order of the President of Russia, the Mi-28N was officially accepted into service as the main attack helicopter.

Mi-28N helicopters, side numbers 09 and 10, yellow, summer 2012 (photo - A.Blogin, http://ruforces-com.livejournal.com).

Mi-28N built in 2012 at the Rostvertol airfield, Rostov-on-Don, March 9, 2012 (photo - Mikhail Mizikaev, http://russianplanes.net/).

The first prototype of the Mi-28N is the OP-1 helicopter, tail number 014, after modifications at the MAKS-2003 air show, 08/23/2003 (photo - Flavien Breitenmoser, http://www.airliners.net).

The Mi-28N helicopter is a prototype of the Mi-28NE helicopter that participated in demonstration flights in India at the MAKS-2011 air show on August 16-21, 2011 (photo - VLAS,).

The dynamic design of the Mi-28N served as the basis for development at the Moscow Helicopter Plant named after. M.L. A mile of projects for new helicopters: the Mi-40 infantry fighting vehicle and the Mi-58 transport and passenger helicopter.

Mass production . Taking into account the positive results of joint state tests of the first prototype of the Mi-28N, the Government of the Russian Federation on December 14, 1997 issued a decree on the completion of work on the Mi-28 and the start of serial production at the Rostov Helicopter Plant. However, due to severe economic situation in the country, the Rostovites managed to complete the construction of the first pre-production helicopter only in March 2004, already in the modification version of the Mi-28N “Night Hunter” - the first helicopter assembled in Rostov (board No. 02, later - 024) made its first flight on March 24, 2004. Before official decision, on December 27, 2005, the first production helicopter, board No. 32, made its first flight. The conclusion issued on March 4, 2006 by the state commission on the release of the pilot batch of Mi-28N was the official permission of Rostvertol OJSC to begin serial production of Mi-28N helicopters, and for customer units to carry out their operation. In the same year, the first production “Night Hunters” began to enter the Russian Air Force and a contract was signed for the supply of 67 Mi-28N helicopters by 2015. Previously, the media announced plans to deliver 50 such machines by 2010. In total, the need for the domestic Air Force is estimated at 300 Night Hunters. The military ministries of a number of foreign countries have expressed interest in purchasing helicopters. It is planned to supply ten Mi-28Ns to the Russian Armed Forces annually. As of 2010, serial production is carried out at the Rostvertol OJSC plant in Rostov-on-Don.

Prehistory of the Mi-28 (posted before the publication of a separate article):

To in-depth design development of the Mi-28 combat helicopter, employees of the Moscow Helicopter Plant named after. M.L. Mil" under the leadership of chief designer M.N. Tishchenko began in 1972. On December 16, 1976, the Central Committee of the CPSU and the Council of Ministers of the USSR adopted a resolution on the development of the Mi-28 combat helicopter. All work was headed by Deputy Chief Designer A.N. Ivanov, M.V. was appointed responsible lead designer. Weinberg. The search for the most rational appearance and work to improve the technical and flight performance of the helicopter were carried out in collaboration with specialized research, development and flight testing organizations.

By the end of 1977, the designers of the Moscow Helicopter Plant named after. M.L. Mil completed the preliminary design, and in 1979 the OKB began detailed design of the rotorcraft and testing of the first experimental samples of units and systems. In August 1980, the government Commission on Military-Industrial Issues, having familiarized itself with the progress of the development of the promising Mi-28 combat helicopter, decided to build prototypes without waiting for official approval of the final layout. Therefore, the first sample of the Mi-28, assembled in July 1982, was refined to the required level during the process of fine-tuning and flight testing.

On November 10, 1982, the crew consisting of the leading test pilot of the plant G.R. Karapetyan and test navigator V.V. Tsygankov was the first to tear a new helicopter off the ground, and on December 19 of the same year, he carried out the first flight in a circle. The helicopter entered joint comparative state tests. In September 1983, the pilot production of the Moscow Helicopter Plant completed the assembly of the second flight prototype. It was used to test weapons.

In 1986, the Mi-28 successfully passed the main part of the state test program, and in next year followed by a government decree to launch the helicopter into mass production. Then the Moscow Helicopter Plant named after. M.L. Mil completed the construction of a pre-production prototype called the Mi-28A. The helicopter was highly appreciated by both domestic and foreign experts. It fully corresponded to its purpose and was superior in many respects to all helicopters of a similar class. The aerobatic and maneuvering characteristics are unique and guarantee high degree survivability in air combat. On May 6, 1993, test pilot Karapetyan performed the “Nesterov loop” for the first time on the Mi-28, and a few days later - the “barrel”.

Total including Mi-28A in 1982-1991. 4 Mi-28 helicopters were built and flown.

Design:

The helicopter is made according to a single-rotor design with a tail rotor, two gas turbine engines, a tricycle landing gear and an auxiliary wing.

The fuselage is all-metal, semi-monocoque, and includes the nose and central parts, as well as the tail and keel booms. In the bow there are two separate armored compartments of the cockpit, in which the navigator-operator's seat is located in front, and the pilot's seat is located behind and above. To increase the combat survivability of the helicopter and the survivability of the crew, there is cockpit armor protection, which includes a set of ceramic tiles glued to the frame of the forward fuselage. The Mi-28N is the only helicopter in the world equipped with side armored glass. The pilot and navigator are separated by an armored partition. The navigator's door is on the left side, and the pilot's door is on the right. Doors and glass are equipped with emergency release mechanisms. In case of emergency leaving the cabins, special ladders are inflated under the doors, protecting the crew from hitting the chassis. At the bottom front of the bow, a viewing and sighting station and a gun mount frame are attached to a stabilized platform. Under the pilot's floor there are blocks of electrical equipment and a sighting, flight and navigation system.

Reservations - fully armored plane-parallel glazing can withstand direct hits from bullets with a caliber of up to 12.7 mm, the cabin armor can withstand hits from 20 mm Vulcan cannon shells.

The rear compartment of the radio equipment has sufficiently spacious free volumes that allow it to be used as a cargo compartment (for transporting airfield equipment when relocating a helicopter or evacuating the crew of another helicopter). The lower position of the tail boom eliminated the possibility of the main rotor blade hitting it during a sharp maneuver. The rear part of the keel beam is designed as a fixed rudder. A stabilizer is attached to the upper part of the keel beam. Under its lower part there is a tail landing gear.

Open rear radio compartment with free volumes. Mi-28N helicopter board No. 12 of the Koronov squadron, air base in Budennovsk, summer 2011 (http://4044415.livejournal.com).

The helicopter's passive protection system ensures the safety of crew members during emergency landing with vertical speed up to 12 m/s. In this case, the magnitude of the overloads is reduced to a level that is physiologically tolerable. The mechanisms that activated the protection system were installed on the shock absorber cylinders of the main landing gear. With their help, the energy-absorbing crew seats are lowered and the longitudinal-transverse control handle is tilted forward, which eliminates the possibility of injury to the pilot. Energy-absorbing seats "Pamir-K" developed by the Zvezda Design Bureau, lowering by 30 cm, protect the crew from overloads that occur during an emergency landing. In an emergency, the pilots are also forced to be pulled to the back of the seat by a harness system to prevent injury.

The wing is cantilevered with four pylons designed for mounting missile, small arms, and bomb weapons and additional fuel tanks. At the ends of the wing in the fairings there are devices for shooting jamming cartridges. In an emergency, the wing can be dropped. The stabilizer control is connected to the rotor collective pitch handle.

The main rotor is five-bladed. The blades have a rectangular shape in plan. The blade spar is made of polymer composite materials forms the nose part according to the shape of the profile. The tail sections, made in the form of a casing made of polymer composite materials with a polymer-hoteplast filler, are attached to it. The main rotor hub is a titanium housing with five remote spherical elastomeric hinges. Metal fluoroplastic and fabric bearings are used in the movable joints of the bushing.

The tail rotor is four-bladed. Designed in an X-shape to reduce noise and increase efficiency. Its bushing consists of two modules, installed one above the other on the hub splines. Each module is a junction of two blade arms. The blade consists of a fiberglass spar and a tail section made of a honeycomb block and fiberglass casing. The main and tail rotor blades are equipped with an electrothermal anti-icing system.

The landing gear is tricycle with a tail wheel. The design of the main landing gear supports includes hydropneumatic shock absorbers with additional emergency travel. The design of the main supports of the lever type allows you to change the helicopter's ground clearance. The fuel system is made in the form of two independent symmetrical power supply systems for each engine with automatic cross-feeding and pumping. It consists of three tanks (two consumable for each engine and one common), located in a fuel tank container, the walls of which are tested with foam rubber. The fuel tanks themselves are filled with explosion-proof polyurethane foam.

The transmission consists of a multi-threaded main gearbox VR-29, two angular gearboxes UR-28, which serve to transmit torque from the engines to the main gearbox, an intermediate gearbox, a tail rotor gearbox and drive transmission shafts.

The control system is booster and consists of four combined steering actuators installed on the main gearbox, which perform the functions of hydraulic boosters and autopilot steering gears. Helicopter control is as comprehensive as possible: the flight controls are located in the pilot's cockpit, and weapons control is located in the navigator-operator's cockpit.

The hydraulic system consists of two independent systems for power supply of combined steering drives and hydraulic dampers. The AC electrical system is powered by two generators driven by a main gearbox.

The hydraulic system consists of two independent systems that serve to power the combined steering actuators of the control systems and the hydraulic damper in the track control system.

The life support system includes air conditioning and oxygen equipment.

Engines: 2 x turboshaft engines TVZ-117VMA (VM modification "A") with a power of 2200 hp each. (2500 hp according to Western data - en.wikipedia.org) developed by the V.Ya. Klimov Design Bureau, in series since 1986. Helicopters manufactured in 2010 and later (starting with white board No. 01) are equipped with VK-2500-02 engines - a modification of the TV3-117 engine. Engine power in emergency mode - 2700 hp. Information on the new engine modification was confirmed in an interview with the Commander-in-Chief of the Russian Air Force dated February 13, 2012.

The independent operation of the engines makes it possible to fly with one operating engine. There are mushroom-shaped dust protection installations at the engine inlets. The engines are equipped with screen-exhaust devices that reduce the helicopter's thermal signature - at least since 2003, a new modern type of electronic devices have been used. The water injection system ensures surge-free operation of the engines during launches of unguided rockets. The AI-9V engine is used as an auxiliary power unit, which also provides drive systems during tests on the ground and supplies warm air for heating the cabins. In the engine compartment of the gear compartment, above the ceiling panel of the central part of the fuselage, there is a fan and an oil cooler.

Screen-exhaust devices of the old type on the Mi-28A (photo from the archive of Dmitry Mironov, http://forum.eagle.ru and http://airbase.ru).

Screen-exhaust devices of a new type on the Mi-28N board No. 37 at the MAKS-2007 exhibition, Ramenskoye, 08/26/2007 (photo - Fedor Borisov, http://www.airliners.net).

Helicopter performance characteristics:

Crew - 2 people (pilot and navigator)

Length - 21155 mm

Fuselage length without propellers - 17010 mm

Main rotor diameter - 17200 mm

Wingspan - 4880 mm

Height - 4800 mm

Maximum take-off weight:

- 12100 kg (combat)

- 12139 kg (distillation)

Normal take-off weight - 10700 kg

Empty weight - 8550 / 8590 kg (according to various sources)

Weight payload- 2300 kg

Fuel weight:

- combat - 634-1271 kg

- distillation - 3029 kg (including 4 PTB)

Fuel reserve in internal tanks - 1900 l

Typical payload and fueling options ( source - ED forums):

| ATGM "Attack" | 8 | 8 | 8 | 16 | 16 | 8 | 16 | 8 | ||||

| UR "Igla" | 4 | 4 | 4 | 4 | ||||||||

| NUR | 2 x B-8V20A | 2 x B-8V20A | 4 x B-8V20A | 2 x B-13L1 | 2 x B-13L1 | 4 x B-13L1 | ||||||

| Availability of NPPU and BKO ammunition | without BKO | without BKO and bk NPPU | ||||||||||

| PTB | 4 PTB | |||||||||||

| Payload weight (kg) | 2250 | 2382 | 2081 | 2530 | 2831 | 3517 | 3216 | 3305 | 3550 | 3550 | 3550 | 3509 |

| Fuel mass (without 30 kg consumed before takeoff, kg) | 1271 | 1271 | 1271 | 1271 | 1271 | 1271 | 1271 | 1271 | 960 | 1261 | 828 | 3029 |

| Incl. in main tanks (kg) | 1271 | 1271 | 1271 | 1271 | 1271 | 1271 | 1271 | 1271 | 960 | 1261 | 828 | 1294 |

Speed:

- maximum - 324 km/h

- cruising - 265 km/h

- side, rear - up to 100 km/h

- angular turn while hovering - up to 90 degrees/s

- yaw rate while hovering - up to 117 deg/s

- angular roll while hovering - 100 deg/s

Range:

- distillation - 1100 km

- practical - 460 km

Ceiling:

- dynamic - 5700 m

- static - 3700 m

- minimum - 5 m

Armament:

- artillery - consists of a fixed movable cannon mount NPPU-28 with a 2A42 cannon of 30 mm caliber. The deflection range of NPPU-28 is: in azimuth ±110°; at elevation angle +13...-40 degrees. The gun's ammunition capacity of 250 shells is located in two boxes with selective two-way feed on the rotating part of the turret. The artillery mount is normally controlled by a navigator-operator.

Artillery mount NPPU-28 of the Mi-28N helicopter board No. 38 - a prototype of the Mi-28NE helicopter - at the MAKS-2011 air show on August 16-21, 2011. The gun is in the extreme left position (photo - VLAS,).

- ATGM - up to 16 anti-tank guided supersonic missiles 9M120 of the "" complex or 9M114 of the "" complex (with radio command guidance systems) can be mounted on external beam holders.

Air-to-air missiles - the Mi-28N is equipped with the installation of air-to-air missiles of the Igla type with an IR homing head with command and hardware modules - Strelets launchers. As of spring 2011, the Strelets KAM was delivered to the air base in Budennovsk.

B-13 NAR block and Strelets launcher with Igla missiles under Mi-28N board No. 38 at the MAKS-2011 air show, August 2011 (photo - VLAS, ).

- other suspended weapons - blocks of unguided missiles, or GUV unified helicopter nacelles in machine-gun and grenade launcher versions, KMGU-2 small cargo containers with mines and small-caliber aerial bombs are mounted on internal holders. The holders can also carry 250 and 500 kg aerial bombs or additional fuel tanks. The helicopter's arsenal also includes heavy unguided missiles, UPK-23-250 cannon containers and ZB-500 incendiary tanks.

Typical payload and armament options, hardpoints from left to right along the helicopter ( source - ED forums, The data is probably outdated):

| Item no. | suspension unit No. 1 | suspension unit No. 2 | suspension unit No. 3 | suspension unit No. 4 | Fuel weight |

| 1 | KMSU | KMSU | KMSU | KMSU | 634 kg |

| 2 | 698 kg | ||||

| 3 | 8 ATGM "Attack" | KMSU | KMSU | 8 ATGM "Attack" | 818 kg |

| 4 | 8 ATGM "Attack" | 8 ATGM "Attack" | 850 kg | ||

| 5 | 1062 kg | ||||

| 6 | 8 ATGM "Attack" | 8 ATGM "Attack" | 1210 kg | ||

| 7 | PTB | PTB | PTB | PTB | 3017 kg |

Equipment:

The avionics complex includes:

- a navigation system consisting of a high-precision inertial system INS-2000 and a strapdown heading SBKV-2V-2 with integration with a satellite navigation system, a Doppler speed and drift meter (DISS) and an airborne signal system (SVS), a radio-technical long-range navigation system (RSDN);

- aerobatic complex

- on-board computer system based on the Baguette-53 computer

- information management system

- multifunctional system for displaying information on LCD indicators MFI-10-6M with a multifunctional console PS-7V with a video information recording device;

- weapon control system

- operator's observation and sighting station - for detecting and recognizing objects, aiming, capturing and automatically tracking objects via television and thermal imaging channels. The composition includes: a line of sight stabilization system, an automatic target tracking system, an optical-television channel, a thermal imaging channel, a laser range finder;

- a pilot observation and aerobatic system with night vision goggles, designed for round-the-clock surveillance of the area, search and detection of objects (landmarks and obstacles). Composition: low-level television channel, thermal imaging channel, laser range finder;

- ATT (automatic thermal television) of the "Okhotnik" family, developed by the Federal State Unitary Enterprise "GRPZ" - provides intelligent processing of video images, as a result of which it becomes possible to see the background target picture in any weather conditions at any time of the day. For the first time among all Okhotnik models, the ATT implements a high-speed digital interface for transmitting video signals during vibrations and roll of the helicopter, and also provides automatic detection and tracking of targets;

- on-board all-round radar

- missile control system

- helmet-mounted target designation and display system

- on-board communications complex KSS-28N-1, provides automatic telecode data exchange with ground control points and others aircraft, equipped with equipment that ensures counter-operation; long-range and short-range open and secret radio communication through a cryptographic protection product and an HF modem. The complex provides simultaneous operation (reception - transmission) via three communication channels, including two telephone channels and one telecode channel;

- radar and laser irradiation warning system, UV radiation direction finder

- radio identification equipment.

Optical-electronic viewing and targeting station with gyro-stabilized fields of view OPS-28 "Tor", developed by Krasnogorsk OMZ named after. Zverev, has optical, low-level television and thermal imaging surveillance channels. A laser range finder and an ATGM control system are structurally combined with the station. To facilitate piloting, the TOES521 turret optical-electronic system developed by the Ural OMZ named after. E.S. Yalamova. This system is also equipped with a laser range finder, thermal imaging and television channels. All generalized information is supplied to multifunctional color liquid crystal displays - two each in the cockpits of the pilot and the navigator-operator; in addition, the pilot has an indicator on the windshield. The Mi-28N has mastered a unified computing environment consisting of three central onboard computers and a number of peripheral computers, which has significantly simplified the onboard software. The helicopter has an extensive internal control system.

Target detection range - 10 km

Instruments in the cockpits of the pilot (left) and navigator-operator (right) of the Mi-28N helicopter. (photo - Alexey Mikheev, Fomin A. Mi-28N - deliveries are growing. // Takeoff. No. 1-2 / 2011).

On-board surveillance and guidance systems for the weapon systems of the Mi-28N helicopter (from the archive of Dmitry Mironov, http://military.tomsk.ru/forum).

It was planned to install the H025 over-the-hub radar on the helicopter. On the helicopter prototypes (OP-1 and OP-2) only mass-dimensional radar mock-ups were installed. By 2007, the main developer, the Ryazan Instrument Plant, had manufactured three experimental radars. One of the three manufactured prototypes of the N025 radar took off for the first time on February 16, 2007 on a Mi-28N helicopter, board No. 36. As of mid-2008, radar tests on this helicopter continued in Chkalovsky. The radar tests were carried out in hovering mode at a height of 8 m - the radar operation was tested in various modes flight, the impact of mechanical influences on the operation of the radar was studied; the test results were considered positive. The design documentation has been improved. The standard installation of an overhead radar is planned for the modification of the Mi-28NM. The purpose of the radar:

- mapping of the earth's surface;

- detection of moving and stationary ground targets;

- measurement of target coordinates;

- ensuring flight safety (detection of flight-hazardous obstacles, including wires and power line supports);

- detection of air targets;

- detection of meteorological formations dangerous for flight, measurement of their intensity and distance to them.

Performance characteristics of radar N-025E (2011):

Frequency range - Ka

Number of simultaneously tracked targets - 4

Range - 20 km

Detection range of hazardous weather formations - up to 100 km

Review time - no more than 1 second

Azimuth viewing area - sector 180 degrees

The viewing area by elevation angle is from -25 to + 15 degrees.

Search sector for ground targets in azimuth - 90 degrees

Search sector for ground targets by elevation angle - 35 degrees

Air target search sector in azimuth - 180 degrees

Air target search sector by elevation angle - 4-12 degrees

Mi-28N board No. 036 testing the first version of the N025 radar (Vzlet. No. 5 / 2008).

Radar N025 produced by the Ryazan Instrument Plant, 2008 (photo - Evgeny Erokhin, http://www.missiles.ru).

Radar N025 produced by the Ryazan Instrument Plant (http://www.grpz.ru).

Overhead radar N025NE at the MAKS-2011 air show, August 2011 (photo - SV, http://forums.eagle.ru).

Mi-28N board No. 36 is yellow, probably with an updated overhead radar. April 1-2, 2012 (photo - kabuki, http://russianplanes.net/).

To protect against air defense systems, the helicopter is equipped with: equipment “for jamming radar stations and guided missiles with infrared and radar homing heads”; helicopter radiation warning equipment radar stations and enemy laser target designators; device for firing UV-26 jamming cartridges for protection against missiles with thermal homing heads.

Mi-28N onboard No. 16, blue, manufactured in 2010, with a full standard set of on-board defense systems, 01/17/2011 (photo - Sergey Ablogin, http://www.airliners.net).

The block for removing interference at the end of the wing console of the Mi-28N helicopter, board No. 12 of the Koronovskaya squadron, air base in Budennovsk, summer 2011 (http://4044415.livejournal.com).

Modifications:

- Mi-28 / product 280 -HAVOC/HAVOC-A- the initial experimental modification of the helicopter, intended for use in daytime and limitedly difficult weather conditions. Released in two copies, tested from 1982 to 1987.

- Mi-28A/ item 286- HAVOC-A- modernized, modification of the Mi-28 created in 1985-1987. The design takes into account all comments and changes made to the experimental samples as they were refined. The helicopter is distinguished by modernized high-altitude TVZ-117VMA engines with a power of 2200 hp. each with improved instrumentation, a modified design of ejector exhaust devices and a modified main gearbox. At the ends of the wings there are containers with cassettes of infrared and radar passive interference. The modification was released in two prototypes.

- Mi-28N “Night Hunter” / product 294 - HAVOC-B- created in 1997, the latest deeply modernized modification with an integrated complex of on-board radio-electronic and instrument equipment and weapons, ensuring round-the-clock combat use in difficult weather conditions and at extremely low altitudes (5 - 15 m) with automatic contouring of the terrain and flying around (bypassing) obstacles using cartographic information and three-dimensional synthesis of terrain images. Since 2006, it has been in serial production at OJSC Rostvertol.

- Mi-28NE / product 296- export version of the Mi-28N. Specialists of JSC Moscow Helicopter Plant named after. M.L.Mil" continues to work on improving the Mi-28N "Night Hunter", introducing the latest achievements of domestic and world helicopter science and technology into the design of its units and systems. A number of new modifications of the helicopter are being prepared for the Russian Air Force and export deliveries, including options with foreign-made units and systems. In the fall of 2010, the helicopter was submitted for tender to the Indian Air Force. The prototype - Mi-28N board No. 38 - was converted by the fall of 2010, and made demonstration flights in India. Helicopter No. 38 was shown at the MAKS-2011 air show on August 16-21, 2011.

- Mi-28UB / product 298- at the beginning of 2010, development began (product code was assigned) for educational version Mi-28N. With identical cockpits for the pilot and operator. As of the summer of 2011, work is underway on the production of the OP-1 prototype. On August 9, 2013, OP-1 made its first flight on the territory of the flight test station of Rostvertol OJSC and it is planned to demonstrate the helicopter at the MAKS-2013 air show. The main difference between the new Mi-28UB and the Mi-28N “Night Hunter” helicopter is a dual hydromechanical control system, which allows you to control the helicopter both from the pilot’s cockpit and from the cockpit of the pilot-operator acting as an instructor. In the new helicopter, the instructor's cabin has been enlarged, the upper part of the pilot's canopy has been expanded, and the configuration of the energy-absorbing seats has been changed (). The Russian Air Force plans to purchase from 40 to 60 Mi-28UB helicopters by 2020. "We will take four to six cars for each military unit, which operates helicopters" ().

The first public photographs of the experimental prototype Mi-28UB - the OP-1 helicopter, 08/09/2013 (photo - Russian Helicopters OJSC, http://www.russianhelicopters.aero).

- Mi-28N serial model, autumn 2011- helicopters of the series are distinguished by improved engine cooling and other improvements. According to the source ( ist. - Aerobatic team...) in the 2011 model, a flaw in the design of the helicopter's main gearbox was corrected, which led to problems and even emergency situations - when operating for more than 2 hours, the gearbox overheated, which led to the rotor stopping.

Helicopter Mi-28N board No. 50 yellow from a batch of helicopters transferred to the Air Force at the air base 344 TsBPiPLS AA on October 8, 2011, Torzhok, Tver region (photo author - Sergey Ablogin, http://ablogin.ru/).

Mi-28N serial No. 07-01 board No. 26 blue in Rostov on Russian Air Fleet Day, 08/19/2012 (photo - ErikRostovSpotter and Andrey Kotkov, http://aviaforum.ru and http://forums.airforce.ru ).

- Mi-28NM- On December 25, 2008, it was reported that the Russian Air Force has begun implementing a project to modernize the Mi-28N helicopter and create the Mi-28NM helicopter, a representative of the press service of the Russian Air Force told RIA Novosti. The draft tactical and technical assignment for the development work on modernizing the Mi-28NM helicopter has received preliminary approval from the Russian Air Force High Command. The helicopter will be standardly equipped with an overhead radar. Serial production of the modification is planned to begin in 2015.

On October 25, 2013, the commander of the 344th Center for Combat Training and Retraining of Army Aviation Flight Personnel in Torzhok, Colonel Andrei Popov, told the media that the Mi-28NM will be significantly different from the Mi-28N - incl. and externally. The helicopter will be equipped with duplicate controls, new equipment and weapons. The design of the helicopter is underway, the completion date has not been announced.

On December 19, 2013, Deputy General Director for Production of the Russian Helicopters holding company Andrei Shibitov told the media that tests of the Mi-28NM will begin in 3 years - i.e. in 2016

Status and chronology: Russia

- 1996 November 14 - first flight of the experimental Mi-28N / OP-1 - board No. 014.

2002 April 24 - resumption of testing of the Mi-28N (No. 014) after equipping it with a new main gearbox VR-29 (instead of VR-28).

2004 March 24 - first flight of the second prototype of the Mi-28N - OP-2, board No. 02, later 024. The helicopter was assembled at the Rostvertol plant in Rostov.

2005 - a contract for a period of 9 years was concluded between the Russian Defense Ministry and OJSC Rostvertol for the supply of 67 Mi-28N helicopters to the Air Force. In 2005-2007 The first 7 pre-production Mi-28N helicopters were built and delivered.

May 2006 - serial Mi-28N board No. 32 joined the state joint testing program.

2006 June 17-25 - 2 Mi-28N helicopters (No. 14 and 32) took part in the Commonwealth Shield 2006 exercise.

January 15, 2008 - a solemn ceremony of transferring two serial Mi-28N Night Hunter helicopters (tail numbers 42 and 43) to the Air Force of the Russian Federation took place in Rostov-on-Don.

2008 August 8 - probably 2 more production helicopters arrived at the Center for Combat Use and Retraining of Flight Personnel No. 344 in Torzhok (military unit 32882). In total, 4 helicopters were delivered to the Air Force in 2008.

2009 March 17 - the first 6 serial Mi-28Ns produced by Rostvertol OJSC arrived at the air base in Budennovsk. Airbase No. 6972 (military unit 40491-D).

2009 summer - 2 helicopters from the center in Torzhok took part in the West-2009 maneuvers held in Belarus.

2009 June 19 - the Mi-28N helicopter (aircraft No. 43) crashed at the Gorokhovets training ground of the Moscow Military District. When firing from a cannon while hovering, due to a failure in the automation, the NUR was launched. Powder gases entered the engine, causing it to surge. Due to a loss of engine power, the pilots decided to make an emergency landing. When touching the ground, the left landing gear fell into a hole, the helicopter overturned onto the left side, as a result of which it was destroyed main rotor and tail boom. The crew of the car was not injured; both pilots managed to get out of the emergency helicopter.

Crash of Mi-28N board No. 43 at the Gorokhovetsky training ground, 06/19/2009 (bottom photo - Sergey Suvorov, from the archive of Dmitry Mironov, http://military.tomsk.ru/forum).

Crash of Mi-28N board No. 43 at the Gorokhovetsky training ground, 06/19/2009 (http://www.ntgs.ru).

Mi-28N helicopter board No. 43 after an accident at the Gorokhovets training ground, the first photo shows the activated means of leaving the helicopter - the navigator’s inflatable ladder, photo 06/19/20/2009 (http://www.liveinternet.ru).

- 2009 December 15 - at the Rostvertol flight test station, the next batch of 4 Mi-28N helicopters was sent to combat units of the Air Force. In total, 10 vehicles were delivered during the year (12 according to other data). The helicopters entered service with the combat squadron at the Budennovsk airbase.

2009 December 25 - The Russian Air Force began implementing a project to modernize the Mi-28N helicopter and create the Mi-28NM helicopter, a representative of the press service of the Russian Air Force told RIA Novosti. The draft tactical and technical assignment for the development work on modernizing the Mi-28NM helicopter has received preliminary approval from the Russian Air Force High Command

2010 beginning of the year - development began (product code assigned) for the training version of the Mi-28N. With identical cockpits for the pilot and operator.

2010 June 18-22 - at a training ground near Primorsko-Akhtarsk, a Mi-28N squadron from the air base in Budennovsk practiced the use of ATGM "Attack".

2010 June 30 - July 3 - tactical flight exercises in which a squadron of 10 Mi-28N from the air base in Budennovsk took part.

October 2010 - the Rostvertol plant in Rostov-on-Don built and delivered 15 Mi-28N to the Russian Air Force. 4 helicopters arrived at the air base in Budennovsk, the rest arrived at the air base in Korenovsk (8 helicopters with white numbers are temporarily located in Budennovsk). Airbase No. 393 in Korenovsk (military unit 35666).

2010 autumn - concluded new contract between the Russian Defense Ministry and OJSC Rostvertol for the supply of an additional 30 Mi-28N helicopters by 2015 (in addition to the 67 units of the 2005 contract).

2011 February 15 - the Mi-28N (aircraft number 05) crashed during a training flight. Chips got into the engine gearbox, after which the crew decided to make an emergency landing. During landing, the car hit the ground with its cabin. The pilots were taken to the Budennovsk hospital, where the crew commander, Lieutenant Colonel Andrei Glyantsev, died from his injuries.

Mi-28N board No. 05 after the disaster, 02/15/2011 (from the archive of Dmitry Mironov, http://military.tomsk.ru/forum).

Mi-28N board No. 05 after the disaster, 02/15/2011 (photos published by Denis Mokrushin, http://twower.livejournal.com).

- 2011 April 8 - the next, 34th serial Mi-28N helicopter took off from the Rostvertol JSC airfield in Rostov-on-Don for its first flight. The machine features a number of improvements, incl. new engine air intakes.

According to unconfirmed information, the photograph shows the Mi-28N helicopter, board No. 43, yellow, restored after the accident on June 19, 2009. The helicopter has a new type of heat exchangers for the main gearbox, equipment for the onboard defense complex - all previously produced helicopters will also be modified. The photo was taken at the testing base of JSC "Rostvertol" in the village of Krestovka, Rostov-on-Don, 05/10/2011 (photo author - Mikhail Mizikaev, http://russianplanes.net).

- August 2011 - unconfirmed information appeared that the infrastructure of airbase No. 393 in Korenovsk was not ready to receive helicopters produced in 2010-2011. intended to be based there. As a result, after standing in Budennovsk, from July 2011 the helicopters were transferred to the training center in Torzhok and, in connection with the release of the calendar resource, after replacing the tail numbers with “Torzhkov” yellow ones, they were used for pilot training. In this vein, at least cars with tail numbers from 109 to 112 have been “renumbered” - the new numbers from 09 to 12 are yellow (see also -).

October 4, 2011 - the media (Izvestia newspaper), citing a source in the military-industrial complex, stated that instead of Mi-28N helicopters, Mi-35M helicopters will be purchased. It's about the purchases for 2011 or the plan for 2012 are not specified, but the order for part of 2011 and for 2012 has probably been sequestered.

October 8, 2011 - Rosvertol delivered 6 Mi-28N helicopters to the Russian Armed Forces. The helicopters were delivered within the framework of the State Defense Order 2011.

2012 January 02 - it was announced in the media that 12 Mi-28N helicopters will enter service at the aviation base in Smolensk in the first quarter of 2012.

2012 August 16 - while performing a training flight in Mozdok, the Mi-28N made a hard landing. There are no casualties, no destruction on the ground. The helicopter received minor damage ().

- 2012 August 19 - on Air Fleet Day in Rostov, the Mi-28N helicopter serial No. 07-01 board No. 26 blue was presented, which, according to unconfirmed reports, is one of 6 helicopters built in 2012 transferred to the Rostvertol plant in 546- 1st Army Aviation Base (directorate - Rostov).

2012 November 5 - the 15th Mi-28N helicopter manufactured in 2012, serial No. 07-07, made its first flight in Rostov.

July 16, 2013 - The Russian Ministry of Defense announces that by the end of summer the Western Military District will receive in Rostov another batch of Mi-28N helicopters and one Mi-26 transport helicopter ().

Export: as of the beginning of 2012, there were no export deliveries.

Algeria:

- July 2007 - Mi-28N underwent a series of demonstration flights in the country. Algeria has expressed interest in purchasing the helicopter, but has outlined requirements for the helicopter that require modifications.

Venezuela- as of July 2007, is showing interest in purchasing a helicopter.

India:

- 2010 autumn - the Mi-28NE helicopter was submitted to the Indian Air Force tender by the state company Rosvooruzhenie and Russian Helicopters OJSC. India plans to purchase 22 helicopters of this class. During 2010, the Mi-28N board No. 38 “yellow” was tested in India.

September 2010 - Mi-28NE prototype - board No. 38 - made several demonstration and test flights in India.

2011 October 25 - the media announced the completion of the competition for the supply of 22 attack helicopters to the Indian Air Force. The Apache Longbow helicopter was declared the winner after comparative tests in 2010. According to the Indian military, the Mi-28N does not meet the tender requirements on 20 points. At the same time, Apache showed superiority in such characteristics as all-weather capability and application capabilities. Later - in 2012 - information appeared in the media ( ist. - Aerobatic team...) that the reasons for the failure of the Mi-28N were technical problems with the main rotor and weapon system.

Iraq:

- 2012 October 9 - Media report that perhaps in April, July or August 2012 a number of agreements were signed with Iraq on the supply of equipment. Incl. It is possible that the delivery of 30 Mi-28N helicopters is planned.

2013 June 17 - RIA Novosti reports the signing of an agreement for the supply of Ka-52 - the RIA correspondent incorrectly understood the statement of the Rosoboronexport representative. In fact, it was about the Mi-28N. Later, information appeared that a contract had been signed for the supply of more than 10 Mi-28NE helicopters.

October 20, 2013 - Media reports that Mi-28NE will be delivered to Iraq by the end of October 2013.

Sources:

ARMS-TASS, news agency. Website http://armstass.su/, 2011

Barabanov M.S. The Russian Air Force is receiving reinforcements. // Independent Military Review. 03/18/2011 http://www.airliners.net/, 2011

ED forums. Website http://forums.eagle.ru, 2011

. Website

Materials provided by: Galushko S. gr. A-532 BSTU "VOENMEH"

The medium-range air-to-air missile R-77-1 (product 170-1) is designed to destroy air targets (fighters, attack aircraft, bombers, military aviation aircraft, helicopters, cruise missiles) at any time of the day, at all angles, in conditions of electronic countermeasures, against the background of the earth and water surface, incl. with multi-channel fire according to the fire-and-forget principle.

Adaptation to foreign media is possible.

The lead developer is the State Machine-Building Design Bureau "Vympel" named after. I.I. Toropova. Export designation RVV-SD.

“Product 170-1” is the result of a deep modernization of the previous generation missile and was developed primarily for placement on the Su-35S fighter (see photo) and Su-34 bomber (see photo). The missile is part of the armament of the fifth-generation fighter T-50 and can be placed on its external hardpoints (see photo 1, photo 2). The upgraded MiG-31BM aircraft can carry up to four new R-77-1 missiles.

The task for the development of Product 170-1 was issued by the Ministry of Defense in 2003. In December 2005, the first four samples were manufactured for preliminary test launches. After the production of 6 more products, the stage of state joint testing was opened in 2006. But in fact, no tests were carried out, because The Su-35S aviation complex capable of using this product has not yet been created. At the end of 2010, the complex was ready for testing. The final launches carried out in the same year resulted in direct hits on the target, confirming all the specified indicators for this class of products. Serial production of the R-77-1 has been launched at the production base of the Vympel Design Bureau.

The next stage in the development of the Vympel IKB line of medium-range missiles was Product 180, intended to arm the fifth-generation fighter T-50. Product 180 is equipped with new combined active-passive radar homing heads developed by the Agat Moscow Research Institute, improved rocket engine. The 542U engine for LKI product 180 was delivered in 2006. For placement inside the T-50 fuselage, the lattice rudders were replaced with flat, non-folding rudders.

A separate direction in the development of medium-range missiles carried out by the Vympel design bureau was the development of the 180-PD (extended range) product, equipped with a 371 ramjet engine.

Compound

RVV-SD is a new generation missile equipped with advanced multi-channel homing systems. Application digital technologies, modern materials and components made it possible to obtain higher performance characteristics compared to previous models. This concerns increasing the range, increasing the accuracy and probability of hitting targets, improving noise immunity, as well as ensuring the use of missiles in any climatic and weather conditions at any time of the year and day.

RVV-SD is a new generation missile equipped with advanced multi-channel homing systems. Application digital technologies, modern materials and components made it possible to obtain higher performance characteristics compared to previous models. This concerns increasing the range, increasing the accuracy and probability of hitting targets, improving noise immunity, as well as ensuring the use of missiles in any climatic and weather conditions at any time of the year and day.

The guidance system is inertial with radio correction and active radar homing. The RVV-SD missile is equipped with a modern monopulse Doppler active radar homing head (ARGSN) 9B-1103M, created by the Moscow Agat Research Institute. The ARGSN 9B-1103M has significantly increased transmitter power and receiver sensitivity, updated software, and improved noise immunity to artificial and natural interference. This made it possible to increase the maximum launch range in the forward hemisphere (FHS) to 110 km and hit targets maneuvering with an overload of up to 12g.

ARGSN 9B-1103M (see) was first demonstrated at the Farnborough 1998 international air show and was subsequently repeatedly modernized.

At the International Forum "Technologies in Mechanical Engineering 2014", the Agat International Research Institute presented new homing heads of the 9B-1103M family, designed, incl. to equip products 170-1 and 180:

- ARGSN 9B-1103M-200PS with an additional passive channel (see)

- ARGSN 9B-1103M-200PA with an additional semi-active channel (see).

According to the developers, the combination of two homing systems with different combat capabilities in one device increases the effectiveness of weapons equipped with this seeker.

The rocket propulsion system is a single-mode solid propellant rocket engine. The fuse is a laser non-contact fuse. The warhead is rod-based, multi-cumulative.

Compared to the RVV-AE, the RVV-SD has improved aerodynamic characteristics due to the use of an elongated nose radio-transparent fairing, a streamlined tail section and recessed mounting points for lattice rudders.

The suspension of the RVV-SD aircraft missile onto the carrier aircraft is carried out using the AKU-170E aircraft ejection device. AKU-170E - piston type, drive type - pyrohydraulic. The EPK-28T-2 squib is used as an energy source.

AKU-170E provides:

- reusable suspension and removal of the rocket without additional adjustments;

- forced ejection with keeping it from turning along the course and roll until the moment of separation;

- use of the missile for 30 days without removing it and carrying out additional checks and adjustments of the ACU.

Everyone knows that in the Union condoms were called “Rubber product number two.” According to widespread opinion, “in the USSR different types rubbers differed in density, this density was distinguished by numbers No. 1, No. 2, etc., and the same numbers were assigned to products depending on what rubber they were made from.” Like, “Rubber product No. 1” is a gas mask, “Rubber product No. 2” is a condom, “Rubber product No. 3” is an eraser, “Rubber product No. 4” is galoshes.

This opinion is wrong. It's all about shyness (after all, the USSR was a very chaste country). It’s just that pharmacies were embarrassed to write on the price tags: “Condom. Size No. 2. Price 2 kopecks,” that’s where they wrote “Rubber product. No. 2. Price 2 kopecks.” - that’s where it came from.

Why size No. 2? Initially there were three sizes of condoms: No. 1 - small, No. 2 - medium, No. 3 - large. And since there was no demand for small sizes (what man admits that he is small without being tortured?), they gradually disappeared from sale. It was also uneconomical to produce a large size condom (and “Economy should be economical,” remember?), one condom No. 3 required a little more rubber, which on a national scale was a big expense, and therefore they also stopped producing them over time. The average size No. 2 became the only one, especially since it was suitable for almost any man: it was designed for 54 mm. wide and 180 mm. in length, and this approximately corresponds to European size XXL - above average.

7 useful lessons we learned from Apple

10 deadliest events in history The Soviet “Setun” is the only computer in the world based on a ternary code 12 previously unreleased photographs by the world's best photographers 10 Greatest Changes of the Last Millennium Mole Man: Man Spent 32 Years Digging in the Desert 10 Attempts to Explain the Existence of Life Without Darwin's Theory of Evolution Unattractive Tutankhamun Pele was so good at football that he “paused” the war in Nigeria with his play.