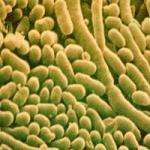

Oil-resistant rubber sheets

Technical plate(technical plate) - a semi-finished product for the manufacture of various rubber products. Essentially, these are rolled rubber strips or a rubber sheet of a certain thickness. With all their diversity, technical plates are standardized according to GOST 7338-90. In industry and other sectors, technical sheet rubber is used in different conditions. They are exposed to high and low temperatures, liquids and gases. Therefore, there are brands of technical plates that are more resistant to certain impacts. The composition of rubber and latex, from which rubber is obtained, is regulated.

vulcanization. At the SANTRADE company you can always buy technical plates and MBS of various thicknesses at the most low prices in Moscow.

Brands of standard technical plates GOST 7338-90

- TMKSH- heat, frost, acid and alkali resistant rubber.

- AMC- weather-oil-resistant rubber (with limited ozone resistance).

- MBS- oil and petrol resistant rubber.

Oil-resistant sheet rubber can be used in an atmosphere of nitrogen or inert gases at fairly high blood pressure. The exact permissible values are given in the tables to the GOST 7338-90 standard.

Sheet rubber prevents fuel, oils and solvents from coming into contact with the surface unless its characteristics specifically indicate oil and petrol resistance, for example MBs rubber.

Most brands of technical plates are designed for use at temperatures from -30ºС to +80ºС. For technical plate TMKShch these limits can be significantly expanded. When overheated, technical rubber undergoes plastic deformation and decomposition; when exposed to excessive freezing, it loses elasticity and becomes brittle.

Technical plate TMKShch GOST 7338-90

TMKShch rubber is the most common and widely used brand of sheet and roll rubber. It is irreplaceable, both as seals and as a gasket material. The TMKSh brand rubber plate consists of rubber and chemical impurities that give it particularly important characteristics:- Heat resistance - maximum operating temperature up to +80ºС.

- Frost resistance - minimum operating temperature from - 30ºС, and in some compositions from - 60ºС.

- Acid resistance - retains its qualities at acid concentrations of up to 20%.

- Alkali resistance - retains its qualities at alkali concentrations of up to 20%.

Heat-freeze-acid-alkali-resistant technical plate (TMKShch plate GOST 7338 90) can be used in salt sea water and wastewater from settling tanks. It withstands the effects of strong (completely dissociating) acids and alkalis in concentrations up to 20%. Rubber cannot be immersed in concentrated sulfuric or hydrochloric acid.

Technical plate MBS GOST 7338-90

MBS technical plate (oil and petrol resistant rubber) - used as gaskets in mechanisms and assemblies in contact with oils and petroleum-based fuels. The MBS plate is widely used in mechanical engineering, instrument making and the oil and gas industry.Gasoline-resistant rubber has a temperature range from -40ºС to +80ºС. The working environment in which oil-resistant rubber exhibits its qualities most effectively is the air of rooms, containers and vessels; inert gases at a pressure from 0.05 to 0.4 MPa or oils and petroleum-based fuels, gasoline at a pressure from 0.05 to 10.0 MPa.

Gasoline-resistant rubber in accordance with GOST 7338-90 is manufactured in rolls with a thickness of 1 to 8 mm. Sheet rubber 10mm or more is produced in the form of sheets and squares. The oil and petrol resistant rubber presented by our company is manufactured by leading manufacturing plants in Russia - "Kurskrezinotekhnika" and "Saransk Rubber Products Plant".

Gasoline-resistant rubber in accordance with GOST 7338-90 is manufactured in rolls with a thickness of 1 to 8 mm. Sheet rubber 10mm or more is produced in the form of sheets and squares. The oil and petrol resistant rubber presented by our company is manufactured by leading manufacturing plants in Russia - "Kurskrezinotekhnika" and "Saransk Rubber Products Plant".

Types, types and classes of rubber technical plates

Technical plate according to GOST 7338-90 is of the following types:- Rubber technical plates.

- Rubber-fabric technical plates. The number of layers of fabric may vary, but there should be no more than one per 2 mm of the thickness of the technical plate. By agreement between the manufacturer and the consumer, it is possible to produce technical plates with special parameters.

Technical rubber and its types:

- Shaped (pieces). They are produced by vulcanization directly in molds.

- Non-shaped (rolled). The continuously extruded mass is vulcanized.

Technical plate classes:

- Class 1. Used at pressures greater than 100 kPa. Thickness 1-20 mm.

- Class 2. Used under pressure less than 100 kPa. Thickness 1-60 mm.

Other characteristics of rubber plates

According to the hardness classification, technical plates are soft, hard and medium hard. Standard technical plates are produced in climatic version T2, OM2, U2, UHL2.- Soft rubber plate (M) - hardness 30-50 units. Shora.

- Rubber plate of medium hardness (C) - hardness 50-65 units. Shora.

- Technical rubber sheet hard (T) - hardness 65-80 units. Shora.

Rubber technical plate is never ideal. It is allowed to have slight variations in color, dullness, a coating of fading components, remnants of powder material, prints of fabric relief, protruding edges after pressing. Characteristics such as porosity, the presence of foreign inclusions, depressions and elevations should not exceed the values defined by GOST 7338-90. Cracks and other serious damage are not allowed on technical plates.

Using technical plates

Technical rubber GOST 7338-90 of standard thickness is easy to cut and chop, and is subject to other types of processing. Products made from technical plates are used for compaction, shock absorption, friction prevention, and vibration damping. They withstand shock loads well. Various floorings, gaskets and linings are made from technical plates.Technical rubber GOST 7338-90 and its markings

In accordance with GOST 7338-90, technical rubber is marked according to a strictly specified classification. For example, sheet rubber 5 mm tmksh s will have the following designation:Rubber plate 2N-I-TMKShch S-5 GOST 7338-90

- 2N - class of technical plate (second class), type - non-shaped (rolled).

- TMKShch is a brand of rubber. (warmth-frost-acid-alkali-resistant)

- C - hardness. IN in this case medium hard plate.

- 5 - thickness in mm.

Rubber plate 1F-I-MBS-M-3 GOST 7338-90

- 1F - class of technical plate (first class), type - shaped (cubes).

- I - subtype of rubber, in this case a rubber plate without a fabric layer.

- MBS - brand - oil and petrol resistant rubber.

- M - hardness. In this case, the plate is soft.

- 3 - thickness in mm.

- Trademark or manufacturer's name

- Stamp technical control

- Date of manufacture (year and quarter)

Why is it worth buying technical plate from our company?

The company "SANTREDE" in Moscow has been supplying domestic enterprises with rubber products, including sheet rubber, for many years, buy or order technical plates non-standard sizes- our company can cope with tasks of any complexity. Over such a long period of time, we have accumulated extensive experience in the selection, storage and production of rubber plates. At our warehouse complexes you can always find the most popular product items, such as:- Sheet rubber from 1 mm;

- Sheet rubber from 2 mm to 50 mm;

- Technical compressed rubber;

- Sheet rubber 5 mm.

Oil and petrol resistant rubber is a high-quality rubber product, designated by the abbreviation MBS. This material is suitable for use in various environments. It is used in any premises, containers and vessels, also in environments with inert gases. Often such rubber is used in a fuel environment if the fuel base is oil or gasoline.

MBS easily withstands temperatures ranging from -30 to +80 degrees Celsius. Gasoline and petroleum products, when exposed to this material, do not affect its shape and elasticity properties. The purpose of the MBS is to seal connections that are not intended as moving elements. This rubber can also be used as a gasket. Gaskets eliminate the possibility of friction between metal surfaces and withstand single impact loads well.

Sheet rubber, which belongs to the category of oil and petrol resistant, can act as a flooring or gasket. This material is produced in various thicknesses, each of which corresponds to a specific GOST. MBS, depending on the components of the composition, can have a number of diverse useful properties. Thus, it is often characterized good performance heat resistance, sound insulation and thermal insulation.

Application of MBS

The most common areas of application of the material are electrical engineering, construction, and mechanical engineering. Often MBS acts as a base when installing pumping and other equipment in order to prevent unwanted vibration effects. The classification of rubber is divided into two main types: according to density and resistance to environments with aggressive manifestations.

MBS 30 rubber is called technical rubber. Its constant characteristic is a thickness of 30 mm. This material is used as a raw material for the manufacture of a wide variety of rubber parts. The parts themselves are subsequently used as seals in fixed-type joints, as well as in the role of various gaskets, floorings and other things.

The main area of application for thirty-millimeter rubber is metal surfaces. It is their contact, in order to avoid the friction process, that is prevented by MBS 30. Since such compounds are mainly found in various types of equipment, rubber is also recognized as technical. That is, these products are not intended for use in other areas, for example, in medicine or food.

Material characteristics

Crude oil-resistant rubber is a mass of one of the categories of rubber compounds that has not been converted into any specific form. The material is provided to clients for the purpose of its further independent formation. Products of the required configuration, size and other parameters can be made from raw rubber.

Molded products made from MBS are capable of working in conditions of interaction with fuel and oils. Range operating temperature raw rubber - from -30 to +100 degrees Celsius. By definition, this material is a rubber compound that can be converted into rubber after undergoing a vulcanization process.

Oil-resistant rubber is a material resistant to technical oils. It is used to make cuffs, seals, diaphragms and other similar products. As a rule, such rubber is produced in the form of sheets with a thickness of 6 to 12 mm. The advantages of this material include: no sulfur content, resistance to oils and the ability to resist swelling.

Complement a wide range of advantages oil resistant rubber characteristics such as resistance to oxidation and high temperature, high electrical resistance and chemical resistance. The material can function properly in the temperature range from -60 to +230 degrees Celsius.

Oil-resistant rubber for transformers, otherwise called oil-resistant silicone, is used as seals for transformers. The material is made primarily from nitrile butadiene rubber. The form of such rubber is sheets, the thickness of which ranges from 6 to 12 mm. In transformers, covers, bushings and flanges are sealed using this material.

The principle of manufacturing seals is the cutting method, when certain sections are cut out or cut out of the material. Such cuttings are joined using an adhesive connector. Transformer rubber can be of two types: ozone-freeze-resistant and universal oil-heat-freeze-resistant.

The geometric form of execution is divided into cords, strips, sheets and rolls. The surface of the technical material must be smooth, only minor inclusions and gas bubbles are allowed.

Rubber technical plates MBS and TMKShch GOST 7338-90 are intended for the manufacture of rubber products used to seal fixed joints, prevent friction between metal surfaces, and to absorb single shock loads, as well as as gaskets, decking and other sealing joints.

Technical plates TMKShch work in the following environment: air, nitrogen, inert gases, water (fresh, sea, industrial, waste without organic solvents and fuels and lubricants), solutions of salts, acids, alkalis with a concentration of no more than 20%.

Classes of technical plates TMKShch:

1 class:

2nd grade:

Types of technical plates TMKShch:

N

F

Types of technical plates TMKShch:

I- rubber;

II- rubber-fabric.

Hardness of technical plates TMKShch (according to the Shore method):

M- soft (40-55);

WITH- average (55-70);

T- hard (70-90).

Example of a symbol:

Plate 2 N - I - TMKShch - S - 3 GOST 7338-90, Where:

2 – class;

N – non-shaped (type);

I – type (rubber);

TMKShch – brand (thermo-acid-alkali-resistant);

3 – thickness (mm).

MBS rubber technical plates(oil and petrol resistant) are designed to work in the following environments: petroleum fuels and lubricants, nitrogen, inert gases.

Classes of MBS technical plates:

1 class: for sealing units operating under pressure above 1 MPa (10 atm);

2nd grade: for sealing units operating under pressure less than 0.5 MPa (5 atm), for decking, linings for single impact loads, etc.

Types of MBS technical plates:

N- non-molded are manufactured without molds (in continuous vulcanizers) in the form of rolls or sheets of various lengths, thickness from 1 mm to 20 mm, width from 800 mm to 1400 mm;

F- molded ones are made by vulcanization in molds in the form of plates or sheets with a thickness of 3 to 80 mm, dimensions 720x720mm, 500x500mm, 520x520mm.

Types of MBS technical plates:

I- rubber;

II- rubber-fabric.

Hardness of MBS technical plates (according to the Shore method):

M- soft (40-55);

WITH- average (55-70);

T- hard (70-90).

The operating temperature of technical plates and products made from them is from -30°C to +80°C.

Example of a symbol:

Plate 2 N - I - MBS - S - 3 GOST 7338-90, Where:

2 – class;

N – non-shaped (type);

I – type (rubber);

MBS – brand (oil and petrol resistant);

C – degree of hardness (C – medium);

3 – thickness (mm).

The ratio of sizes, weight and type of packaging of MBS and TMKSh rubber plates:

| THICKNESS (mm) | TYPE OF PACKAGING | WEIGHT 1 sq.m (kg) |

| 1,0 | roll | 1,25 |

| 1,5 | roll | 1,90 |

| 2,0 | roll | 2,50 |

| 3,0 | roll/plate | 3,75 |

| 4,0 | roll/plate | 5,00 |

| 5,0 | roll/plate | 6,25 |

| 6,0 | roll/plate | 7,50 |

| 8,0 | roll/plate | 10,00 |

| 10,0 | roll/plate | 12,50 |

| 12,0 | roll/plate | 15,00 |

| 15,0 | roll/plate | 18,75 |

| 20,0 | plate | 25,00 |

| 25,0 | plate | 31,25 |

| 30,0 | plate | 37,50 |

| 40,0 | plate | 50,00 |

| 50,0 | plate | 62,50 |

Oil and petrol resistant rubber- high-quality rubber products, designated by the abbreviation MBS. This material is suitable for use in various environments. It is used in any premises, containers and vessels, also in environments with inert gases. Often such rubber is used in the energy sector if the main medium is oil..

Transformer rubber (oil-resistant rubber) is made from nitrile butadiene rubber (SKN-26, SKN-18) in the form of sheets with a thickness of 6 to 12 mm. Oil-resistant rubber is used for sealing covers, bushings, flanges of oil power transformers.

Purpose oil resistant rubber MBS– sealing connections that are not intended to be moving elements. This rubber can also be used as a gasket. Gaskets eliminate the possibility of friction between metal surfaces and withstand single impact loads well.

Sealing gaskets and rings for transformers are made from technical grade oil and petrol resistant rubber (MBR) by casting into special molds. It is recommended to cut rubber sheets up to 6 mm thick using punch knives.

Oil-resistant rubber for transformers is manufactured in 2 types:

- UM – universal oil-heat-freeze-resistant version

- OM – ozone-freeze-resistant

Nominal geometric parameters of products made of oil-resistant rubber

|

Product type |

Length, mm |

Width, mm |

Thickness, mm |

Diameter, mm |

|

8 |

Technical performance rubber in media

and operating conditions GOST 12855-77

Quality control

The surface of technical rubber must be smooth. The following are not allowed on the main surface and sections of the product: inclusions and gas bubbles of more than 0.5 mm for plates up to 5 mm thick; 0.75 mm – for thicknesses 5-10 mm, 1.0 for thicknesses 10-20 mm; 1.5 mm for plates thicker than 20 mm. The total area of air bubbles should not exceed 10 cm2. per 1 sq.m. products.

Folds formed during the bandaging process of the product should not exceed 4 mm in width, 100 mm in length and be greater than the tolerance range for the thickness of the roll in depth. Acceptable delamination along the edges and ends of the roll or plate is up to 5 mm in length and 1 mm in width.

Physical and mechanical properties

|

Parameter name |

Type of technical plate |

|

|

Density, g/cm3 |

||

|

Shore hardness, A |

||

|

Change in mass when the product is kept for 24 hours in SZhR-2 oil at a temperature of 100°C, % |

Not regulated |

|

|

Tensile strength, MPa |

||

|

Relative extension, % |

||

|

Relative residual deformation under compressive force in air for 24 hours at temperature: |

||

|

Frost resistance coefficient for elastic recovery after compressive deformations, not less than: |

||

Marking

Labeling indelible paint Each rubber product is subject to Markings include:

- trademark

- symbol

- date of issue indicating quarter and year

- STK stamp

Transportation and storage

Transformer plates should be stored in closed warehouses at the following temperature conditions:

- from 0 to +25°C – normal storage mode, duration - within the guaranteed storage period

- from +25 to +35°C – no more than 80 days

- from +35 to +40°C – no more than 15 days

If technical plates were stored in subzero temperatures, before use they should be kept for 3 hours at a temperature of 50°C, or for 24 hours at a temperature of 15°C. During storage Rubber products must be protected from direct sunlight, oil, gasoline, kerosene, their vapors, acids, alkalis, gases, as well as other substances capable of destroying rubber.

Transformer rubber sheets can be transported by all types of transport. When transporting in closed containers, the products may not be packaged.

If transformer plates are transported at temperatures below -30°C, the products should be reliably protected from impact loads and deformations. You can unpack technical plates after exposure to negative temperatures only after they have been kept for a day at a temperature from 0°C to +25°C.