Where is non-ferrous metallurgy located? Non-ferrous metallurgy of Russia. Geography of non-ferrous metallurgy. Metallurgical plants and largest factories in Russia

"Vyksa Metallurgical Plant" - The main products of VSW. Located in the city of Vyksa Nizhny Novgorod region. Since 1999, it has been part of the United Metallurgical Company. Today. VSW products comply with global and domestic standards quality. Vyksa Metallurgical Plant. Wheels for Sapsan trains are produced in Vyksa. Metallurgical enterprises of Russia. The surroundings of Vyksa were ideal for creating a new metallurgical production.

“Mining and metallurgy” - The main countries for the production of non-ferrous metals. Factors of production. Mining centers. Production sizes. Ferrous metallurgy centers. Mining powers. Mining industry and metallurgy. Bauxite mining. international trade iron ore. World production. Non-ferrous metallurgy centers. Metallurgy. Mining industry.

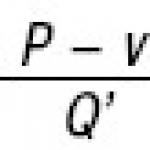

“Metallurgy Test” - Types of metallurgy. Cherepovets Metallurgical Plant. Metal sacrificed to the “red devil”. A set of industries producing a variety of metals. Picture of metallurgical complex. Economic difficulties. Ferrous metallurgy enterprises. An idea of methods for obtaining metals. Steel quality. Large centers of metallurgy. Formula. Metallurgy. Hydrogen. Metallurgical complex.

"Mining and metallurgical complex" - Heavy metals base. Non-ferrous metals. Location of metallurgical production. Metallurgical bases of Russia. Placement of MSC. Consumer factor. Raw materials. Features of metallurgy. Mechanical engineering complex. Metallurgical plants full cycle. Enterprises. Composition of MSC. Ferrous metallurgy center. Composition and significance of MK. Metallurgical complex.

“Metallurgical complex of the Russian Federation” - The influence of scientific and technological revolution on ferrous metallurgy. Industry. Electrometallurgy. Metallurgical complex. Cast iron. Large metallurgical companies of the world. Ferrous metallurgy. OPEC composition. Practical work. Combination of stocks coal and iron ore. Oxygen converter process. Ferrous metallurgy. Industry development trends. The main “coal” and “iron ore” bridges. Placement factors.

“Composition of the metallurgical complex” - Steel production in the Russian Federation. Placement factors. Metallurgical complex. Composition and significance of the complex. The significance of the metallurgical complex. Introduction to the metallurgical complex. Prospects. Types of ferrous metallurgy enterprises. Geography of the industry. Metallurgy centers in the Russian Federation. Ferrous metallurgy. Combination. Industry of the complex. More than 60% of all steel is produced in Russia. Stages of the production process.

Non-ferrous metallurgy includes the extraction, beneficiation of non-ferrous metal ores and smelting of non-ferrous metals and their alloys.

Russia has a powerful non-ferrous metallurgy, distinguishing feature which is development based on own resources. By physical properties and purpose, non-ferrous metals can be divided into heavy (copper, lead, zinc, tin, nickel) and light (aluminum, titanium, magnesium). Based on this division, a distinction is made between light metal metallurgy and metallurgy. heavy metals.

Several main bases of non-ferrous metallurgy have been formed on the territory of Russia. Their differences in specialization are explained by the dissimilarity in the geography of light metals (aluminum, titanium-magnesium industry) and heavy metals (copper, lead-zinc, tin, nickel-cobalt industries).

The location of non-ferrous metallurgy enterprises depends on many economic and natural conditions, especially on the raw material factor. In addition to raw materials, the fuel and energy factor plays a significant role.

The production of heavy non-ferrous metals, due to the low energy demand, is confined to the areas of raw material extraction for reserves, mining and enrichment of copper ores.

The reserves of copper and nickel ores in Russia are still sufficient not only to satisfy domestic needs, but also for export needs. However, if new deposits are not discovered and developed, a crisis situation may soon arise with the production of the corresponding metals, as well as platinoids. This is largely due to the fact that the rich copper-nickel ores of Norilsk, which provide 70% of copper production and 90% of nickel production in the country, are being depleted; about half of the copper ore mining capacity in the Urals, which provided up to 20% of copper, has been abandoned. The supply of copper concentrates from Mongolia, Kazakhstan, and Uzbekistan is decreasing, so the search and exploration of copper and nickel ores remains an important task.

Significant reserves of copper and copper-nickel ores are available in Siberia. In addition to the well-known copper-nickel ore deposits in the lower reaches of the Yenisei - Norilsk, Talnakh, Oktyabrsky - there is another copper ore deposit - Udokanskoye - located in the north-east of the Chita region. It is the largest in terms of reserves in the Russian Federation and the third in terms of reserves in the world (more than 1.2 billion tons of ore with a copper content of 18-20 million tons). However, this deposit is characterized by complex mining and geological development conditions that require the development of special mining technology; in addition, the quality of the ore is such that its processing also requires the development of special technology.

An important place in the production of copper, nickel and other non-ferrous metals belongs to Norilsk Nickel, which is a world leader in the production of non-ferrous and precious metals(copper, nickel, cobalt, gold, silver, selenium, rhodium, palladium, platinum, osmium, iridium, ruthenium, tellurium, etc.). Norilsk Nickel provides 1/5 of the world market demand for nickel and cobalt, 40% of the world production of platinum metals.

The lead-zinc industry as a whole gravitates towards areas where polymetallic ores are distributed. Such deposits include Sadonskoye (North Caucasus), Salairskoye ( Western Siberia), Nerchinskoye (Eastern Siberia) and Dalnegorskoye (Far East). The centers of the Nickel-Cobalt industry are the cities of Norilsk (Eastern Siberia), Nickel and Monchegorsk (Northern economic region).

Extraction of lead and zinc ores from the bowels of Russia covers only 25 and 43% of Russia's domestic consumption. The supply of Russian industry with these metals depends mainly on Kazakhstan, since the Russian Federation does not have its own lead factories. There are enough zinc factories in Russia; in Siberia there is the Belovsky Zinc Plant.

In Siberia there are explored deposits of lead-zinc ores. In terms of reserves, the Gorevskoye, Ozernoye and Kholodnenskoye fields are distinguished, which are assessed as promising, but have not yet been developed, since this requires significant funds and time.

An increase in lead production in Russia is envisaged through the expansion of capacities based on technical reconstruction and implementation advanced technology at the lead plant PA "Dalpolimetal". It is also planned to organize production here for processing secondary lead and expand the Verkhneivensky secondary lead plant.

The production of light metals requires a large amount of energy. Therefore, the concentration of enterprises smelting light metals near sources of cheap energy is the most important principle their placement.

The raw materials for aluminum production are bauxites from the North-Western region (the city of Boksitogorsk), the Urals (the city of Severouralsk), nephelines from the Kola Peninsula (the city of Kirovsk) and the south of Siberia (the city of Goryachegorsk). From this aluminum raw material, aluminum oxide - alumina - is isolated in mining areas. Smelting aluminum metal from it requires a lot of electricity. Therefore, aluminum smelters are built near large power plants, mainly hydroelectric power stations (Bratskaya, Krasnoyarsk, etc.).

Russia has a powerful aluminum industry (90% of CIS production) and fully covers the domestic demand for aluminum, and also exports it in significant quantities. Currently, Russia ranks second in the world in the production of primary aluminum after the United States.

The production of primary aluminum in Russia is carried out by 11 plants, with 80% of the output coming from five large Siberian plants: Bratsk, Krasnoyarsk, Sayan, Irkutsk and Novokuznetsk. This industry is one of the most stable in the Russian economy in terms of volume dynamics. The crisis of the 90s had little effect on the production volumes of primary aluminum compared to enterprises in other branches of non-ferrous metallurgy, but significantly changed the structure of its consumption: if previously the main consumers of aluminum industry products were military-industrial complex enterprises (52%), now the bulk of the production aluminum is exported.

The main raw material for the production of primary aluminum is alumina. Its production is material-intensive, so it is produced in places where bauxite and nepheline ores are mined. Most Russian bauxites are inferior in quality to their foreign counterparts. Today, 55 bauxite deposits are known in Russia, but only 10 of them are actively developed.

About 50% of aluminum is produced from our own ore and alumina, the rest is imported from Ukraine, Kazakhstan and foreign countries. Currently, aluminum smelters receive raw materials from Australia, France, Greece, India and other countries.

The development of a high-quality raw material base for the aluminum industry remains an important problem, for which the necessary prerequisites exist (primarily, the development of bauxite in Komi, the use of nepheline concentrates in the processing of nepheline-apatite ores of the Khibiny, improvement of bauxite mining technology at the North Ural mine).

There are also reserves of aluminum raw materials in Siberia: Kiya-Shaltyrsky nephelines in the Kemerovo region, Goryachegorsk nephelines and Chadobetsky bauxites in the Krasnoyarsk Territory, Boksonsky bauxites in Buryatia. However, these deposits are usually characterized by low quality raw materials, small stocks and placement in undeveloped and hard-to-reach areas.

The titanium-magnesium industry is located mainly in the Urals, both in the areas of raw material extraction (Bereznikovsky magnesium plant, and in areas of cheap energy (Ust-Kamenogorsk titanium-magnesium plant). The final stage of titanium-magnesium metallurgy - processing of metals and their alloys - is most often located in areas of consumption finished products.

Currently, not a single titanium deposit is being developed in Russia. Until now, 96% of Russia's need for titanium production has been met by supplies of titanium concentrates from Ukraine. We operate the Bereznikovsky titanium-magnesium plant and the Klyuchevsky ferroalloy plant in the Urals. Ukraine also supplies titanium pigment, which is not produced in our country.

Russia has the necessary conditions to establish own production facilities titanium and zirconium, since the proven reserves of these raw materials in Russia are sufficient (loparite and nepheline-apatite ores of the Kola Peninsula, Yaregskoye deposit in Komi, placers in Western and Eastern Siberia). In Siberia, titanomagnetite ore deposits can be used for titanium production, for example, Krichininskoye in the Chita region.

The mineral resource base created to date in terms of the volume of explored reserves is able to meet Russia's need for titanium products in the future, but, at the same time, it should be taken into account that the possibility of satisfying Russia's need for titanium through its associated extraction at existing enterprises is excluded. Of the created reserve fund of deposits, those that are feasible for priority development in terms of the degree of preparedness are Yaregskoye in Komi, Medvedevskoye in the Chelyabinsk region and Tuganskoye in the Tomsk region.

In the near future, our country can meet its needs for tin, tungsten and molybdenum from its own resources, however most of explored deposits are characterized low quality ore Therefore, it is necessary to search for new deposits, but we must not forget about the existing reserves: move quickly to underground mining of tungsten and molybdenum at the Primorsky Mining and Processing Plant, increase production capacity at the tin deposits of the Solnechny Mining and Processing Plant at Far East.

The main tin deposit in Siberia is Sherlovaya Mountain in the Chita region. The main deposits of tungsten and molybdenum in Siberia are Dzhidinskoye in Buryatia, Davendinskoye in Zhireken and Orlovskoye in the Chita region.

The metallurgical complex of Russia is the main synonym for the well-being and prosperity of our entire state, its confidence in the future.

First of all, it serves as the basis for all existing mechanical engineering. Understanding this, let’s find out which enterprises are included in the mining and metallurgical complex.

These are mainly those industries that mine, enrich, smelt, roll and process raw materials. The company has its own clear structure:

- Ferrous metallurgy - ore and non-metallic raw materials.

- Non-ferrous metallurgy: light metals (magnesium, titanium, aluminum) and heavy metals (nickel, lead, copper, tin).

Ferrous metallurgy

An industry with its own nuances. It is important to understand that not only metal is important for it, but also mining and subsequent processing.

An industry with its own nuances. It is important to understand that not only metal is important for it, but also mining and subsequent processing.

Its important features are highlighted:

- more than half of the products serve as the basis for the country’s entire mechanical engineering industry;

- a quarter of the products are used in the creation of structures with increased load capacity.

Ferrous metallurgy is production, coking of coal, secondary alloys, production of refractories and much more. Enterprises included in the ferrous metallurgy are of the greatest importance and, in fact, are the basis of the industry of the entire state as a whole.

The main thing is that around them there are production facilities for processing various wastes, especially after cast iron smelting.

The most common satellite of ferrous metallurgy is considered to be metal-intensive mechanical engineering and electrical power production. This industry has great prospects for the future.

Ferrous metallurgy centers in Russia

First of all, it should be remembered that Russia has always been and today is the absolute leader in terms of ferrous metal production density. And this primacy is without the right to transfer to other states. Our country confidently holds its position here. Let's name the most important centers of ferrous metallurgy in Russia:

- Urals with iron and ore mining;

- Kuzbass with coal mining;

- Novokuznetsk;

- Location of KMA;

- Cherepovets.

The metallurgical map of the country is structurally divided into three main groups. They are studied at school and are the basic knowledge of a modern cultured person. This:

- Ural;

- Siberia;

- Central part.

Ural metallurgical base

It is this that is the main and, perhaps, the most powerful in terms of European and world indicators. It is characterized by a high concentration of production.

The city of Magnitogorsk is of paramount importance in its history. There is a famous metallurgical plant there. This is the oldest and hottest “heart” of ferrous metallurgy.

It produces:

- 53% of all cast iron;

- 57% of all steel;

- 53% of ferrous metals of all indicators that were produced in the former USSR.

Such production facilities are located near raw materials (Ural, Norilsk) and energy (Kuzbass, Eastern Siberia). Now the Ural metallurgy is in the process of modernization and further development.

Central metallurgical base

It includes cyclical production plants. Presented in the cities: Cherepovets, Lipetsk, Tula and Stary Oskol. Reserves form this base iron ores. They are located at a depth of up to 800 meters, which is shallow depth.

The Oskol Electrometallurgical Plant has been launched and is successfully operating. It introduced an avant-garde method without a blast furnace metallurgical process.

Siberian metallurgical base

Perhaps it has one peculiarity: it is the “youngest” of the existing bases today. Its formation began during the USSR period. Approximately one fifth of the total volume of raw materials for cast iron is produced in Siberia.

The Siberian base is a plant in Kuznetsk and a plant in Novokuznetsk. Novokuznetsk is considered the capital of Siberian metallurgy and a leader in production quality.

Metallurgical plants and largest factories in Russia

The most powerful full-cycle centers are: Magnitogorsk, Chelyabinsk, Nizhny Tagil, Beloretsky, Ashinsky, Chusovskoy, Oskolsky and a number of others. All of them have great development prospects. Their geography, without exaggeration, is enormous.

Non-ferrous metallurgy

This area is occupied with the development and enrichment of ores, participating in their high-quality smelting. According to its characteristics and intended purpose, it is divided into categories: heavy, light and valuable. Its copper smelting centers are almost closed cities, with their own infrastructure and life.

Main areas of non-ferrous metallurgy in Russia

The opening of such areas entirely depends on: the economy, the environment, and raw materials. This is the Urals, which includes factories in Krasnouralsk, Kirovgrad and Mednogorsk, which are always built near production. This improves the quality of production and the turnover of raw materials.

Development of metallurgy in Russia

Development is characterized by high rates and volumes. Therefore, huge Russia is in the lead and is constantly increasing its exports. Our country produces: 6% iron, 12% aluminum, 22% nickel and 28% titanium. Read more about thisIt is reasonable to look at the information in the production tables presented below.

Map of metallurgy in Russia

For convenience and clarity, special maps and atlases have been produced. They can be viewed and ordered on the Internet. They are very colorful and comfortable. The main centers with all divisions are indicated in detail there: copper smelters, places for the extraction of ore and non-ferrous metals, and much more.

Below are maps of ferrous and non-ferrous metallurgy in Russia.

Factors for locating metallurgical plants in Russia

The fundamental factors influencing the location of plants across the country are literally the following:

- raw materials;

- fuel;

- consumption (this is a detailed table of raw materials, fuel, small and large roads).

Conclusion

Now we know: there is a clear division into ferrous and non-ferrous metallurgy. This distribution of mining, enrichment and smelting depends directly on the main components: raw materials, fuel and consumption. Our country is a European leader in this area. The three main geographical pillars on which it stands are: the Center, the Urals and Siberia.

Non-ferrous metallurgy is not only a set of activities for the production of non-ferrous metals (mining, beneficiation, metallurgical processing, production of castings of pure metals and alloys based on them), but also the processing of scrap non-ferrous metals.

Scientific and technological progress does not stand still, and non-ferrous metals today are widely used to develop innovative structural materials. The domestic metallurgical industry alone produces about 70 types of alloys using a variety of raw materials.

Due to the low content of the required component in the ore and impurities of other elements, non-ferrous metallurgy is an energy-intensive industry and has a complex structure. Thus, the ore contains no more than 5% copper, and no more than 5.5% zinc and lead. Pyrites mined in the Urals are multicomponent, and they contain about 30 chemical elements.

Non-ferrous metals are divided into six categories, according to their physical properties and purpose:

- Heavy. They have high density and, accordingly, weight. These include Cu, Ni, Pb, Zn, Sn.

- Lungs. They are light in weight due to their low specific density. These include: Al, Mg, Ti, Na, Ka, Li.

- Small: Hg, Co, Bi, Cd, As, Sb.

- Alloying. Mainly used to produce steels and alloys with necessary qualities. These are W, Mo, Ta, Nb, V.

- Noble ones. Widely known and used for making jewelry. Among them are Au, Ag, Pt.

- Rare earth, trace: Se, Zr, Ga, In, Tl, Ge.

Industry specifics

Non-ferrous metal ores, as mentioned above, contain a small amount of the mined element. Therefore, for a ton of the same copper, up to 100 tons of ore are needed. Due to the large demand for raw materials, non-ferrous metallurgy is, for the most part, located close to its raw material base.

Non-ferrous ores require large quantities fuel or electricity. Energy costs reach half total costs associated with the smelting of 1 ton of metal. In this regard, metallurgical enterprises are located in close proximity to electricity producers.

The production of rare metals is mainly based on reduction from compounds. Raw materials come from intermediate stages of ore beneficiation. Due to the small volumes and difficulty of production, laboratories are engaged in obtaining rare metals.

Industry Composition

Types of non-ferrous metallurgy include industries related to the production of certain types of metals. Thus, the following sectors can be distinguished in aggregate:

- copper production;

- aluminum production;

- production of nickel and cobalt;

- tin production;

- lead and zinc production;

- gold mining.

The production of nickel is closely related to the place of extraction of nickel ores, which are located on the Kola Peninsula and in the Norilsk region of Siberia. Many branches of non-ferrous metallurgy are characterized by multi-stage metallurgical processing of intermediate products.

On this basis it is effective A complex approach. This is a raw material for the production of other related metals. Waste recycling is accompanied by the production of materials used not only in other branches of heavy engineering, but also in the chemical and construction industries.

Metallurgy of heavy metals

Copper production

The main stages of obtaining pure copper are the smelting of blister copper and its further refining. Blister copper is mined from ores, and the low concentration of copper in the Ural copper pyrites and its large volumes do not allow the transfer of production facilities from the Urals. The reserves are: cuprous sandstones, copper-molybdenum, copper-nickel ores.

Refining of copper and melting of secondary raw materials is carried out at enterprises that are remote from the sources of mining and primary smelting. They are favored by the low cost of electricity, since up to 5 kW of energy per hour is consumed to produce a ton of copper.

The utilization of sulfur dioxide gases with subsequent processing served as the start for the production of sulfuric acid in chemical industry. It produces phosphate mineral fertilizers from apatite residues.

Obtaining lead and zinc

The metallurgy of non-ferrous metals such as lead and zinc has complex territorial fragmentation. Ore is mined in the North Caucasus, Transbaikalia, Kuzbass and the Far East. And enrichment and metallurgical processing are carried out not only near ore extraction sites, but also in other territories with developed metallurgy.

Lead and zinc concentrates are rich in chemical elemental base. However, raw materials have different percentages of elements, which is why zinc and lead cannot always be obtained in pure form. Therefore, technological processes in the regions are different:

- In Transbaikalia, only concentrates are obtained.

- Lead and zinc concentrate are produced in the Far East.

- Zinc and lead concentrate are produced in Kuzbass.

- Redistribution is underway in the North Caucasus.

- Zinc is produced in the Urals.

Metallurgy of light metals

The most common light metal is aluminum. Alloys based on it have properties inherent in structural and special steels.

To obtain aluminum, the raw materials are bauxite, alunite, and nepheline. Production is divided into two stages:

- At the first stage, alumina is obtained and a large volume of raw materials is required.

- In the second stage, aluminum is produced using the electrolytic method, which requires inexpensive energy. Therefore, the production stages are located in different territories.

The production of aluminum and alloys is concentrated in industrial centers. Scrap is also supplied here for recycling, which ultimately reduces the cost of the finished product.

Non-ferrous metals are divided into several groups according to their physical properties and purpose:

- heavy - copper, lead, zinc, tin, nickel;

- light - aluminum, magnesium, titanium, lithium, etc.;

- small - bismuth, cadmium, antimony, arsenic, cobalt, mercury:

- alloying agents - tungsten, molybdenum, tantalum, niobium, vanadium;

- noble - gold, silver, platinum and platinoids;

- rare and scattered - zirconium, gallium, indium, thallium, germanium, selenium, etc.

Non-ferrous metallurgy in Russia produces about 70 various types metals Three countries in the world have such a complete set of production - the USA, Germany, Japan.

Features of the raw material base of non-ferrous metallurgy:

- extremely low quantitative content of useful components in raw materials (copper from 1 to 5%, lead-zinc from 1.5 to 5.5%, etc.), i.e. to obtain 1 ton of copper it is necessary to process at least 100 tons of ore;

- exceptional multicomponent nature of raw materials (for example: Ural pyrites contain copper, iron, sulfur, gold, cadmium, silver and others, up to 30 elements in total);

- high fuel intensity and energy intensity of raw materials during processing.

A feature of non-ferrous metallurgy is the high energy intensity of raw materials in the process of their preparation for metallurgical processing and processing. In this regard, a distinction is made between fuel-intensive and electricity-intensive industries. High fuel intensity is typical, for example, for the production of nickel, alumina from nephelines, and blister copper. The production of aluminum, magnesium, calcium, titanium, etc. is characterized by increased electrical intensity. In the industry as a whole, the share of fuel and energy costs ranges from 10 to 50-65% of the total costs for 1 ton of products produced. This feature of production determines the location of non-ferrous metallurgy industries in regions that are best supplied with electricity.

Non-ferrous metallurgy industries

Main branches of non-ferrous metallurgy:

- aluminum industry;

- copper smelting or copper industry;

- lead-zinc industry;

- nickel-cobalt industry;

- tin mining industry;

- gold mining industry;

- diamond mining industry.

It should be noted that in the distribution of non-ferrous metallurgy there are usually no clearly limited areas of location (or metallurgical bases). This is due to two reasons: firstly, non-ferrous metallurgy has a complex industry structure; secondly, in many sub-sectors there is a territorial gap between the extraction and enrichment of raw materials and the smelting of finished metal.

Aluminum industry

Aluminum has high structural properties, lightness, sufficient mechanical strength, high thermal and electrical conductivity, which ensures its use in mechanical engineering, construction, and the production of consumer goods. Aluminum alloys(duralumin, silumin, etc.) according to mechanical properties not inferior to high-grade steels.

The main raw materials for aluminum production are bauxite; nephelines and alunites, which are complex raw materials, are also used. The technological process consists of two main stages: the production of alumina and the production of aluminum metal. Geographically, these processes are in many cases separated, since the first stage is material-intensive and gravitates towards sources of raw materials, and the second is oriented in its placement towards sources of cheap energy.

In Russia, all centers for the production of aluminum metal (with the exception of the Urals) are to one degree or another removed from raw materials, being located near hydroelectric power stations (Volgograd, Volkhov, Kandalaksha, Nadvoitsy, Bratsk, Shelekhov, Krasnoyarsk, Sayanogorsk) and partly where large power plants operate on cheap fuel (Novokuznetsk).

Joint production of alumina and aluminum is carried out in the North-Western region (Volkhov) and in the Urals (Krasnoturinsk and Kamensk-Uralsky).

The aluminum industry, among other branches of non-ferrous metallurgy, stands out for its largest scale of production. The most powerful enterprises for alumina operate in Achinsk, Krasnoturinsk, Kamensk-Uralsky and Pikalyov, for aluminum - in Bratsk, Krasnoyarsk, Sayanogorsk and Irkutsk (Shelekhov). Eastern Siberia produces almost 4/5 of the total amount of aluminum in the country.

Until 2007, the domestic market for aluminum products was represented by two companies: SUAL-Holding (SUAL Group) and Russian Aluminum (RUSAL).

In 2006-2007 There was a merger of the aluminum and alumina assets of the RUSAL company, which ranked third in the world in aluminum production, the SUAL group, one of the world's top ten aluminum producers, and the Swiss company Glencore, and the world's largest aluminum corporation, United Russian Aluminum Company (UK), was created RUSAL).

The main feature of the company is vertical integration within the production cycle of successive technological stages for the extraction and processing of raw materials, production of primary metal, as well as semi-finished and finished products from aluminum and its alloys.

Copper smelting or copper industry

Copper has high electrical conductivity and malleability, and is widely used in mechanical engineering, especially in the electrical industry, the construction of power and communication lines, as well as in the production of alloys with other metals.

The copper industry, due to the relatively low content of concentrates, is confined (excluding the refining of crude metal) to areas with raw material resources.

The main type of ores currently used in Russia for copper production are copper pyrites, which are represented mainly in the Urals (Krasnouralskoye, Revdinskoye, Blavinskoye, Sibaiskoye, Gaiskoye and other deposits). An important reserve is cuprous sandstones concentrated in Eastern Siberia (Udokan deposit). Copper-molybdenum ores are also found. Copper-nickel and polymetallic ores are used as additional raw materials.

The main copper production region is the Urals, which is characterized by the predominance of metallurgical processing over mining and beneficiation. Therefore, they are forced to use imported (mostly Kazakh) concentrates.

In the Urals there are enterprises for the production of blister copper and its refining. The former include the Krasnouralsk, Kirovograd, Sredneuralsk (Revda), Karabash and Mednogorsk copper smelters, and the latter include the Kyshtym and Verkhnepymensk copper-electrolyte plants.

Characterized by widespread recycling of waste for chemical purposes. At the copper smelters of Krasnouralsk, Kirovograd and Revda, sulfur dioxide gases serve as the feedstock for the production of sulfuric acid. In Krasnouralsk and Revda, phosphate fertilizers are produced based on sulfuric acid and imported apatite concentrates.

In the future, it is planned to bring into circulation new sources of raw materials for copper production. To develop the unique Udokan deposit in Eastern Siberia, a mining company of the same name (UMC) was created with the participation of American-Chinese capital. The deposit, the third largest in the world, is located near the Chara station on the BAM.

Refining, as the final stage of copper production, has little direct connection with raw materials. In fact, it is located either where there is metallurgical processing, forming specialized enterprises, or in combination with the smelting of ferrous metal, or in areas of mass consumption of finished products (Moscow, St. Petersburg, Kolchugino, etc.). A favorable condition is the availability of cheap energy (1 ton of electrolytic copper consumes 3.5-5 kW/h).

Nickel-cobalt industry

Nickel, which has high hardness, is an alloying metal and is used as protective coating metal products. Nickel is part of valuable alloys with other non-ferrous metals.

Cobalt, mined from nickel ores, is used to produce cobalt alloys: magnetic, heat-resistant, super-hard, corrosion-resistant.

The nickel-cobalt industry is most closely associated with sources of raw materials, which is due to the low content of intermediate products (matte and matte) obtained during the processing of the original ores. In Russia, two types of ores are exploited: sulfide (copper-nickel), which are known on the Kola Peninsula (Nickel) and in the lower reaches of the Yenisei (Norilsk), and oxidized ores in the Urals (Verkhniy Ufaley, Orsk, Rezh). The Norilsk region is especially rich in sulfide ores. Sources of raw materials have been identified here (Talnakh and Oktyabrskoye deposits), which makes it possible to further expand the metallurgical processing of nickel.

Norilsk region - largest center integrated use of copper-nickel ores. At the plant operating here, which combines all stages technological process- from raw materials to finished products, nickel, cobalt, platinum (together with platinum group metals), copper and some other rare metals are produced. By recycling waste we obtain sulfuric acid, soda and other chemical products.

OJSC * Mining and Metallurgical Company "Norilsk" Nickel is Russia's largest and one of the world's largest companies producing precious and non-ferrous metals. It accounts for more than 20% of global nickel production, more than 10% of cobalt and 3% of copper. On domestic market OJSC MMC Norilsk Nickel accounts for about 96% of all nickel produced in the country, 55% of copper, 95% of cobalt.

Lead-zinc industry focuses on the raw material and fuel base: Kuzbass - Salair, Transbaikalia - Nerchinsk, Far East - Dalnegorsk, etc. The tin industry is developed in the Far East: Sherlovogorsky, Khrustalnensky, Solnechny GOK.

Diamond mining industry. Diamonds are one of the most important income sources of domestic exports. The country receives about $1.5 billion annually from their sales. Currently, almost all domestic diamonds are mined in Yakutia. In two diamond-bearing areas of the Vilyui River basin, there are several mines, including such well-known ones as Yubileiny and Udachny (85% of total production). In the eastern regions of the country, diamonds were also found in Eastern Siberia (Krasnoyarsk Territory and Irkutsk Region). Joint-stock company "AL ROSA" is one of the world leaders in the field of exploration, production and sale of diamonds, polished diamond production. AK "AL ROSA" mines 97% of all diamonds Russian Federation. The company's share in global diamond production is 25%.

Development prospects are outlined in federal programs: “Development of the ore base of non-ferrous metallurgy”, “National program for the development of metallurgy in Russia”.